Page 80 - Handbook of Surface Improvement and Modification

P. 80

6.1 Methods and mechanisms of tack enhancement 75

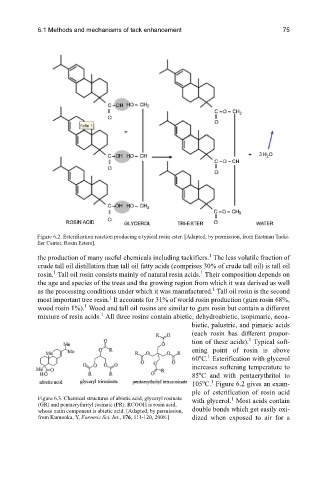

Figure 6.2. Esterification reaction producing a typical rosin ester. [Adapted, by permission, from Eastman Tacki-

fier Center, Rosin Esters].

1

the production of many useful chemicals including tackifiers. The less volatile fraction of

crude tall oil distillation than tall oil fatty acids (comprises 30% of crude tall oil) is tall oil

1

1

rosin. Tall oil rosin consists mainly of natural resin acids. Their composition depends on

the age and species of the trees and the growing region from which it was derived as well

1

as the processing conditions under which it was manufactured. Tall oil rosin is the second

1

most important tree resin. It accounts for 31% of world rosin production (gum rosin 68%,

1

wood rosin 1%). Wood and tall oil rosins are similar to gum rosin but contain a different

1

mixture of resin acids. All three rosins contain abietic, dehydroabietic, isopimaric, neoa-

bietic, palustric, and pimaric acids

(each rosin has different propor-

1

tion of these acids). Typical soft-

ening point of rosin is above

1

o

60 C. Esterification with glycerol

increases softening temperature to

o

85 C and with pentaerythritol to

o

1

105 C. Figure 6.2 gives an exam-

ple of esterification of rosin acid

Figure 6.3. Chemical structures of abietic acid, glyceryl rosinate with glycerol. Most acids contain

1

(GR) and pentaerythrityl rosinate (PR). RCOOH is rosin acid,

whose main component is abietic acid. [Adapted, by permission, double bonds which get easily oxi-

from Kumooka, Y, Forensic Sci. Int., 176, 111-120, 2008.] dized when exposed to air for a