Page 82 - Handbook of Surface Improvement and Modification

P. 82

6.1 Methods and mechanisms of tack enhancement 77

leum-derived C9-hydrocarbons. The

copolymer resins are cycloaliphatic aro-

matic hydrocarbon resins and maleic anhy-

dride-modified hydrocarbon resins are

useful in promoting pigment wetting.

Hydrogenated hydrocarbon resins are

produced using the controlled hydrogena-

tion of basic or pure monomer aromatic res-

ins. They are usually colorless and very

stable to heat, weathering, and oxidation.

The hydrocarbon resins are frequently

used as tackifiers in the pressure-sensitive

3

and hot-melt adhesives markets. The

amount of the hydrocarbon resin used in

these formulations sometimes equals to the

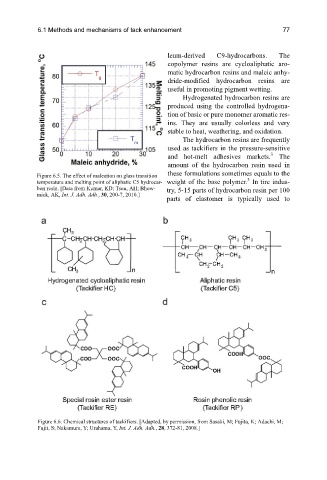

Figure 6.5. The effect of maleation on glass transition

3

temperature and melting point of aliphatic C5 hydrocar- weight of the base polymer. In tire indus-

bon resin. [Data from Kumar, KD; Tsou, AH; Bhow- try, 5-15 parts of hydrocarbon resin per 100

mick, AK, Int. J. Adh. Adh., 30, 200-7, 2010.]

parts of elastomer is typically used to

Figure 6.6. Chemical structures of tackifiers. [Adapted, by permission, from Sasaki, M; Fujita, K; Adachi, M;

Fujii, S; Nakamura, Y; Urahama, Y, Int. J. Adh. Adh., 28, 372-81, 2008.]