Page 81 - Handbook of Surface Improvement and Modification

P. 81

76 Tackifiers

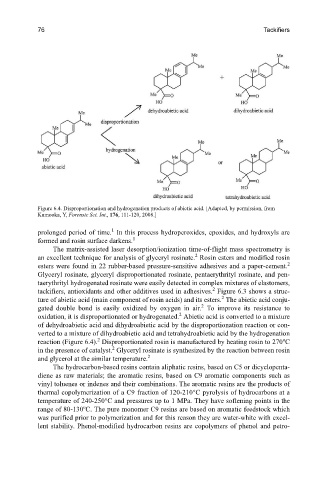

Figure 6.4. Disproportionation and hydrogenation products of abietic acid. [Adapted, by permission, from

Kumooka, Y, Forensic Sci. Int., 176, 111-120, 2008.]

1

prolonged period of time. In this process hydroperoxides, epoxides, and hydroxyls are

1

formed and rosin surface darkens.

The matrix-assisted laser desorption/ionization time-of-flight mass spectrometry is

2

an excellent technique for analysis of glyceryl rosinate. Rosin esters and modified rosin

esters were found in 22 rubber-based pressure-sensitive adhesives and a paper-cement. 2

Glyceryl rosinate, glyceryl disproportionated rosinate, pentaerythrityl rosinate, and pen-

taerythrityl hydrogenated rosinate were easily detected in complex mixtures of elastomers,

2

tackifiers, antioxidants and other additives used in adhesives. Figure 6.3 shows a struc-

2

ture of abietic acid (main component of rosin acids) and its esters. The abietic acid conju-

2

gated double bond is easily oxidized by oxygen in air. To improve its resistance to

2

oxidation, it is disproportionated or hydrogenated. Abietic acid is converted to a mixture

of dehydroabietic acid and dihydroabietic acid by the disproportionation reaction or con-

verted to a mixture of dihydroabietic acid and tetrahydroabietic acid by the hydrogenation

o

2

reaction (Figure 6.4). Disproportionated rosin is manufactured by heating rosin to 270 C

2

in the presence of catalyst. Glyceryl rosinate is synthesized by the reaction between rosin

2

and glycerol at the similar temperature.

The hydrocarbon-based resins contain aliphatic resins, based on C5 or dicyclopenta-

diene as raw materials; the aromatic resins, based on C9 aromatic components such as

vinyl toluenes or indenes and their combinations. The aromatic resins are the products of

thermal copolymerization of a C9 fraction of 120-210°C pyrolysis of hydrocarbons at a

temperature of 240-250°C and pressures up to 1 MPa. They have softening points in the

o

range of 80-130 C. The pure monomer C9 resins are based on aromatic feedstock which

was purified prior to polymerization and for this reason they are water-white with excel-

lent stability. Phenol-modified hydrocarbon resins are copolymers of phenol and petro-