Page 135 - High Power Laser Handbook

P. 135

104 Diode Lasers Semiconductor Laser Diodes 105

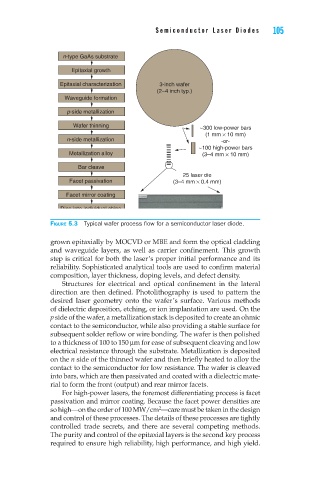

n-type GaAs substrate

Epitaxial growth

Epitaxial characterization 3-inch wafer

(2~4 inch typ.)

Waveguide formation

p-side metallization

Wafer thinning

~300 low-power bars

(1 mm × 10 mm)

n-side metallization -or-

~100 high-power bars

Metallization alloy (3–4 mm × 10 mm)

Bar cleave

25 laser die

Facet passivation (3–4 mm × 0.4 mm)

Facet mirror coating

Dice into individual chips

Figure 5.3 Typical wafer process flow for a semiconductor laser diode.

grown epitaxially by MOCVD or MBE and form the optical cladding

and waveguide layers, as well as carrier confinement. This growth

step is critical for both the laser’s proper initial performance and its

reliability. Sophisticated analytical tools are used to confirm material

composition, layer thickness, doping levels, and defect density.

Structures for electrical and optical confinement in the lateral

direction are then defined. Photolithography is used to pattern the

desired laser geometry onto the wafer’s surface. Various methods

of dielectric deposition, etching, or ion implantation are used. On the

p side of the wafer, a metallization stack is deposited to create an ohmic

contact to the semiconductor, while also providing a stable surface for

subsequent solder reflow or wire bonding. The wafer is then polished

to a thickness of 100 to 150 mm for ease of subsequent cleaving and low

electrical resistance through the substrate. Metallization is deposited

on the n side of the thinned wafer and then briefly heated to alloy the

contact to the semiconductor for low resistance. The wafer is cleaved

into bars, which are then passivated and coated with a dielectric mate-

rial to form the front (output) and rear mirror facets.

For high-power lasers, the foremost differentiating process is facet

passivation and mirror coating. Because the facet power densities are

2

so high—on the order of 100 MW/cm —care must be taken in the design

and control of these processes. The details of these processes are tightly

controlled trade secrets, and there are several competing methods.

The purity and control of the epitaxial layers is the second key process

required to ensure high reliability, high performance, and high yield.