Page 148 - High Power Laser Handbook

P. 148

118 Diode Lasers

5.35%

1.0%

0.9%

0.8%

0.7%

Failure percent 0.6%

0.5%

0.4%

0.3%

0.2% 0.18%

0.13%

0.09%

0.1% 0.08% 0.07% 0.08% 0.08%

0.0%

0–20 20–40 40–60 60–80 80–100 100–120 120–140 140–160

Time interval (hr)

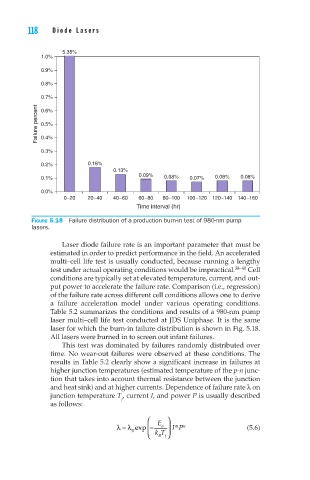

Figure 5.18 Failure distribution of a production burn-in test of 980-nm pump

lasers.

Laser diode failure rate is an important parameter that must be

estimated in order to predict performance in the field. An accelerated

multi–cell life test is usually conducted, because running a lengthy

test under actual operating conditions would be impractical. 38–40 Cell

conditions are typically set at elevated temperature, current, and out-

put power to accelerate the failure rate. Comparison (i.e., regression)

of the failure rate across different cell conditions allows one to derive

a failure acceleration model under various operating conditions.

Table 5.2 summarizes the conditions and results of a 980-nm pump

laser multi–cell life test conducted at JDS Uniphase. It is the same

laser for which the burn-in failure distribution is shown in Fig. 5.18.

All lasers were burned in to screen out infant failures.

This test was dominated by failures randomly distributed over

time. No wear-out failures were observed at these conditions. The

results in Table 5.2 clearly show a significant increase in failures at

higher junction temperatures (estimated temperature of the p-n junc-

tion that takes into account thermal resistance between the junction

and heat sink) and at higher currents. Dependence of failure rate λ on

junction temperature T , current I, and power P is usually described

j

as follows:

E

n

m

λ λ = exp − a IP (5.6)

0 kT

Bj

119