Page 154 - How To Implement Lean Manufacturing

P. 154

132 Cha pte r Se v e n

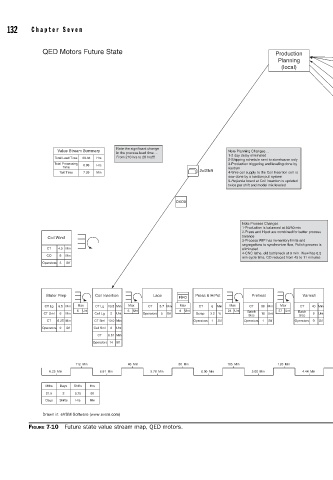

QED Motors Future State Production

Planning

(local)

Note the significant change

Value Stream Summary Note Planning Changes…

in the process lead time….

Total Lead Time 20.38 Hrs From 210 hrs to 20 hrs!!! 1-2 day delay eliminated

2-Shipping schedule sent to storehouse only

Total Processing 0.98 Hrs 3-Production triggering and leveling done by

Time kanban

2x/Shift

Takt Time 7.09 Min 4-Wire coil supply to the Coil Insertion cell is

now done by a kanban pull system

5-Heijunka board at Coil Insertion is updated

twice per shift and model mix leveled

Note Process Changes

1-Production is balanced at 50/50 mix

2-Press and Hipot are combined for better process

Coil Wind balance

3-ProcessWIP hasinvnentorylimits and

segregations to synchronize flow, Polish process is

CT 4.5 Min eliminated

4-CNC lathe, old bottleneck at 9 min. Now has 6.5

CO 6 Min

min cycle time, CO reduced from 45 to 11 minutes

Operators 3 Stf

Stator Prep Coil Insertion Lace Press & HiPot Preheat Varnish

CT Lg 6.5 Min Max CT Lg 13.5 Min Max CT 5.7 Min Max CT 6 Min Max CT 90 Min Max CT 40 Min

6 Unt 5 Unt 4 Unt 24 Unt Batch 27 Unt Batch

CT Sml 6 Min Cell Lg 2 Unt Operators 5 Stf Scrap 3.2 % 18 Unt 9 Unt

Size Size

CT 6.25 Min CT Sml 13.0 Min Operators 1 Stf Operators 1 Stf Operators 0 Stf

Operators 2 Stf Cell Sml 2 Unt

CT 6.61 Min

Operators 14 Stf

112 Min 46 Min 30 Min 165 Min 120 Min

6.25 Min 6.61 Min 5.70 Min 6.00 Min 5.00 Min 4.44 Min

Mths Days Shifts Hrs

21.5 2 9.75 60

Days Shifts Hrs Min

Drawn in: eVSM Software (www.evsm.com)

FIGURE 7-10 Future state value stream map, QED motors.