Page 151 - How To Implement Lean Manufacturing

P. 151

How to Do Lean—The Four Strategies to Becoming Lean 129

precludes the ability to take actions on these larger value stream maps. If actions are not

the result of the value stream map, then the map has lost most of its effectiveness.

The key benefit to value stream mapping is that it focuses on the entire value stream

to find system wastes and tries to avoid the pitfall of optimizing some local situation at

the expense of the overall optimization of the entire value stream. The strength of value

stream mapping may also be its weakness. It is not uncommon to find large wastes in

cells, for example, which are not detailed on VSMs. If this is the case, large wastes can

go unnoticed. This is a problem to those who only use VSMs in their battle to find and

eliminate waste. Value steam mapping is only one tool in the battle for waste reduction,

and to truly attack wastes, many tools are required.

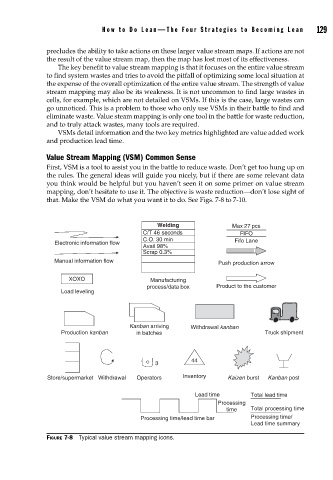

VSMs detail information and the two key metrics highlighted are value added work

and production lead time.

Value Stream Mapping (VSM) Common Sense

First, VSM is a tool to assist you in the battle to reduce waste. Don’t get too hung up on

the rules. The general ideas will guide you nicely, but if there are some relevant data

you think would be helpful but you haven’t seen it on some primer on value stream

mapping, don’t hesitate to use it. The objective is waste reduction—don’t lose sight of

that. Make the VSM do what you want it to do. See Figs. 7-8 to 7-10.

Welding Max 27 pcs

C/T 46 seconds FIFO

C.O. 30 min Fifo Lane

Electronic information flow

Avail 98%

Scrap 0.3%

Manual information flow Push production arrow

XOXO Manufacturing

process/data box Product to the customer

Load leveling

Kanban arriving Withdrawal kanban

Production kanban in batches Truck shipment

44

3

Store/supermarket Withdrawal Operators Inventory Kaizen burst Kanban post

Lead time Total lead time

Processing

time Total processing time

Processing time/lead time bar Processing time/

Lead time summary

FIGURE 7-8 Typical value stream mapping icons.