Page 150 - How To Implement Lean Manufacturing

P. 150

128 Cha pte r Se v e n

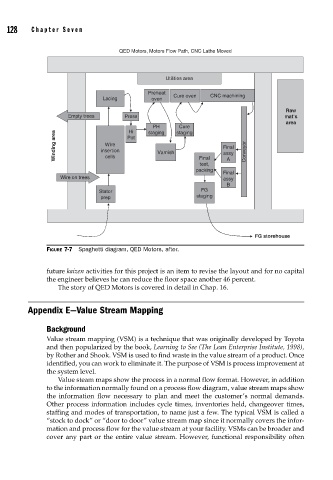

QED Motors, Motors Flow Path, CNC Lathe Moved

Utilities area

Preheat

Lacing oven Cure oven CNC machining

Raw

Empty trees Press mat’s

area

PH staging

Cure

Hi

Winding area insertion Pot Varnish Final Conveyor

staging

Wire

assy

cells

Final

test, A

packing

Final

Wire on trees assy

B

Stator FG

prep staging

FG storehouse

FIGURE 7-7 Spaghetti diagram, QED Motors, after.

future kaizen activities for this project is an item to revise the layout and for no capital

the engineer believes he can reduce the floor space another 46 percent.

The story of QED Motors is covered in detail in Chap. 16.

Appendix E—Value Stream Mapping

Background

Value stream mapping (VSM) is a technique that was originally developed by Toyota

and then popularized by the book, Learning to See (The Lean Enterprise Institute, 1998),

by Rother and Shook. VSM is used to find waste in the value stream of a product. Once

identified, you can work to eliminate it. The purpose of VSM is process improvement at

the system level.

Value steam maps show the process in a normal flow format. However, in addition

to the information normally found on a process flow diagram, value stream maps show

the information flow necessary to plan and meet the customer’s normal demands.

Other process information includes cycle times, inventories held, changeover times,

staffing and modes of transportation, to name just a few. The typical VSM is called a

“stock to dock” or “door to door” value stream map since it normally covers the infor-

mation and process flow for the value stream at your facility. VSMs can be broader and

cover any part or the entire value stream. However, functional responsibility often