Page 152 - How To Implement Lean Manufacturing

P. 152

130 Cha pte r Se v e n

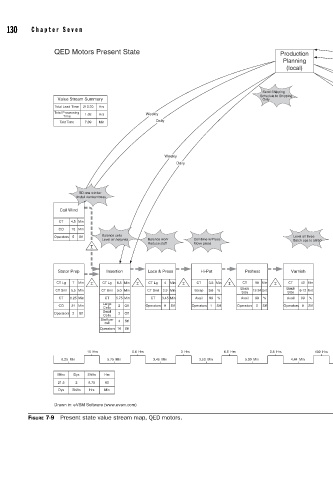

QED Motors Present State Production

Planning

(local)

Send Shipping

Schedule to Shipping

Value Stream Summary Only

Total Lead Time 210.20 Hrs

Total Processing 1.02 Hrs Weekly

Time

Takt Time 7.09 Min Daily

Weekly

Daily

SD one winder

Install kanban trees

Coil Wind

CT 4.5 Min

CO 10 Min

Operators 5 Stf Balance cells Level all three

Level w/ heijunka Balance work Combine w/Press Batch ops to 50/50

Reduce staff Move press

Stator Prep Insertion Lace & Press Hi-Pot Preheat Varnish

CT Lg 7 Min CT Lg 6.5 Min CT Lg 4 Min CT 3.5 Min CT 90 Min CT 40 Min

Batch Batch

CT Sml 5.5 Min CT Sml 5.0 Min CT Sml 2.9 Min Scrap 9.6 % 12-24 Unt 6-12 Unt

Size Size

CT 6.25 Min CT 5.75 Min CT 3.45 Min Avail 99 % Avail 99 % Avail 99 %

Large

CO 21 Min 2 Off Operators 9 Stf Operators 1 Stf Operators 0 Stf Operators 0 Stf

Cells

Small

Operators 2 Stf 2 Off

Cells

Staff per 4 Stf

cell

Operators 16 Stf

15 Hrs 0.6 Hrs 3 Hrs 6.6 Hrs 0.8 Hrs 109

109 Hrs

6.25 Min 5.75 Min 3.45 Min 3.50 Min 5.00 Min 4.44 Min

Mths Dys Shifts Hrs

21.5 2 9.75 60

Dys Shifts Hrs Min

Drawn in: eVSM Software (www.evsm.com)

FIGURE 7-9 Present state value stream map, QED motors.