Page 149 - How To Implement Lean Manufacturing

P. 149

How to Do Lean—The Four Strategies to Becoming Lean 127

Appendix D—The Spaghetti Diagram

Background

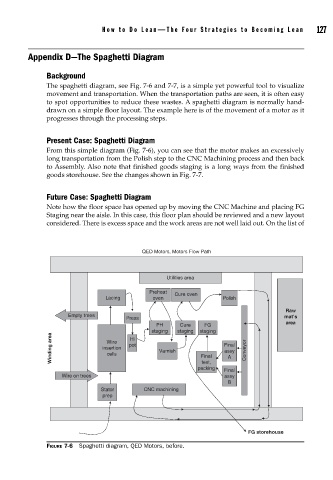

The spaghetti diagram, see Fig. 7-6 and 7-7, is a simple yet powerful tool to visualize

movement and transportation. When the transportation paths are seen, it is often easy

to spot opportunities to reduce these wastes. A spaghetti diagram is normally hand-

drawn on a simple floor layout. The example here is of the movement of a motor as it

progresses through the processing steps.

Present Case: Spaghetti Diagram

From this simple diagram (Fig. 7-6), you can see that the motor makes an excessively

long transportation from the Polish step to the CNC Machining process and then back

to Assembly. Also note that finished goods staging is a long ways from the finished

goods storehouse. See the changes shown in Fig. 7-7.

Future Case: Spaghetti Diagram

Note how the floor space has opened up by moving the CNC Machine and placing FG

Staging near the aisle. In this case, this floor plan should be reviewed and a new layout

considered. There is excess space and the work areas are not well laid out. On the list of

QED Motors, Motors Flow Path

Utilities area

Preheat

Cure oven

Lacing oven Polish

Raw

Empty trees mat’s

Press

area

PH Cure FG

staging staging staging

Winding area insertion pot Varnish Final Final Conveyor

Hi

Wire

assy

cells

A

test,

packing Final

Wire on trees assy

B

Stator CNC machining

prep

FG storehouse

FIGURE 7-6 Spaghetti diagram, QED Motors, before.