Page 271 - How To Implement Lean Manufacturing

P. 271

3/9/2005, 2 shift

J. O. Bengineer

Date

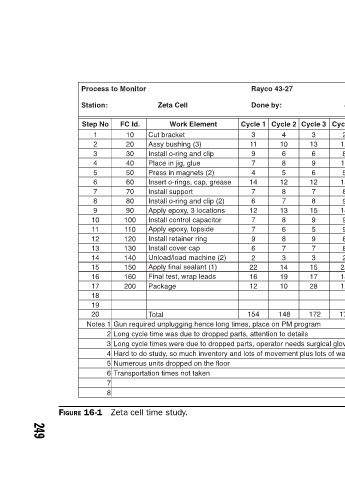

Cycle 3 Final Average Range Low High Cycle 8 Cycle 7 Cycle 6 Cycle 5 3 4.4 9 2 11 3 11 5 2 3 12 12.9 9 10 19 12 19 13 12 13 7 7.3 3 6 9 7 8 7 8 6 9 9.1 4 7 11 9 10 10 11 9 6 6.9 13 4 17 17 7 4 5 6 13 13.9 7 12 19 14 13 19 13 12 8 7.7 2 7 9 7 9 8 8 7 8 9.7 17 6 23

Rayco 43-27 Done by: Cycle 2 Cycle 1 4 3 10 11 6 9 8 7 5 4 12 14 8 7 7 6 13 12 8 7 6 7 8 9 7 6 3 2 14 22 19 16 10 12 148 154 Long cycle times were due to dropped parts, operator needs surgical gloves Hard to do study, so much inventory and lots of movement plus lots of wait times

Work Element Insert o-rings, cap, grease Install o-ring and clip (2) Apply epoxy, 3 locations Install control capacitor Unload/load machine (2) Apply final sealant (1) Gun required unplugging hence long times, place on PM program Long cycle time was due to dropped parts, attention to details

Zeta Cell Cut bracket Assy bushing (3) Install o-ring and clip Place in jig, glue Press in magnets (2) Install support Apply epoxy, topside Install retainer ring Install cover cap Final test, wrap leads Package Total Numerous units dropped on the floor Transportation times not taken Zeta cell time study.

Process to Monitor Station: FC Id. Step No 10 1 20 2 30 3 40 4 50 5 60 6 70 7 80 8 90 9 100 10 110 11 120 12 130 13 140 14 150 15 160 16 200 17 18 19 20 Notes 1 2 3 4 5 6 7 8 FIGURE 16-1

249