Page 274 - How To Implement Lean Manufacturing

P. 274

Using the Pr escription—Thr ee Case Studies 251

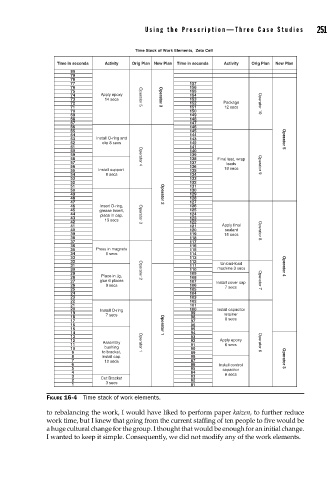

Time Stack of Work Elements, Zeta Cell

Time in seconds Activity Orig Plan New Plan Time in seconds Activity Orig Plan New Plan

80

79

78

77 157

76 156

75 155

74 Apply epoxy Operator 5 154

73 14 secs Operator 3 153

72 152 Package Operator 10

71 151 12 secs

70 150

69 149

68 148

67 147

66 146

65 145

64 144

63 Install O-ring and 143 Operator 5

62 clip 8 secs 142

61 141

60 140

59 Operator 4 139

58 138 Final test, wrap

57 137 leads

56 136 18 secs Operator 9

55 Install support 135

54 8 secs 134

53 133

52 132

51 131

50 130

49 Operator 2 129

48 128

47 127

46 Insert O-ring, 126

45 grease insert, 125

44 place in cap. Operator 3 124

43 13 secs 123

42 122

41 121 Apply final

40 120 sealant Operator 8

39 119 15 secs

38 118

37 117

36 116

35 Press in magnets 115

34 6 secs 114

33 113

32 112 Unload-load

31 111 Operator 4

30 Operator 2 110 machine 3 secs

29 109

28 Place in jig, 108

27 glue 6 places 107 Install cover cap Operator 7

26 9 secs 106 7 secs

25 105

24 104

23 103

22 102

21 101

20 Install O-ring 100 Install capacitor

19 7 secs 99 retainer

18 98 8 secs

17 97

16 Operator 1 96

15 95

14 94

13 93

12 Assembly Operator 1 92 Apply epoxy Operator 6

11 91 6 secs

10 bushing 90

9 to bracket, 89

8 install cap. 88

7 12 seds 87 Operator 3

6 86 Install control

5 85 capacitor

4 84 8 secs

3 Cut Bracket 83

2 82

1 3 secs 81

FIGURE 16-4 Time stack of work elements.

to rebalancing the work, I would have liked to perform paper kaizen, to further reduce

work time, but I knew that going from the current staffing of ten people to five would be

a huge cultural change for the group. I thought that would be enough for an initial change.

I wanted to keep it simple. Consequently, we did not modify any of the work elements.