Page 59 - Improving Machinery Reliability

P. 59

Requirements SpeciJicution 31

GAS REFERENCE

OVERHEAD

// /, // //

// // //

6-INCH (152.mm) BOTTOM OUTLET NOZZLE

- ---

DRAIN OR FILL CONNECTION

TRANSFER BARRIER

(BLADDER.TYPE)

VESSEL

VC (SEE NOTE 3)

BLAODER.LIMITER DEVICE

TO SUPPLY HEADER

(SEE NOTES 1 AN

NOW:

1. Option A.14a: If the pump is for seal oil only. Ihe purchaser may specify a switch to stop the pump.

2. Option A.14b: If pumps are lor a combined lube- and seal-oil syslem. the purchaser may specify an

alarm switch.

3. Option A-14c: The purchaser may specily an accumulator with an isvlation bladder.

4. Option A.14d:Thepurchaser may specify thedesired failure action for the loopactualedlevelcontrol

vdve.

5. The purchaser may specify a valved vent if one is available

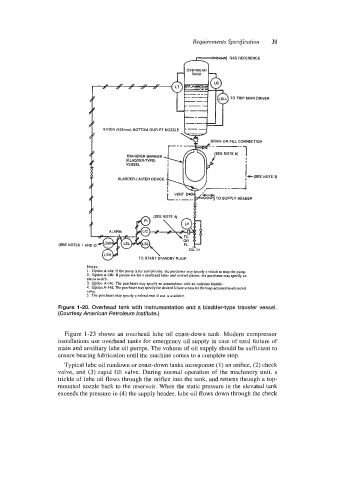

Figure 1-20. Overhead tank with instrumentation and a bladder-type transfer vessel.

(Courtesy American Petroleum Institute.)

Figure 1-23 shows an overhead lube oil coast-down tank. Modern compressor

installations use overhead tanks for emergency oil supply in case of total failure of

main and auxiliary lube oil pumps. The volume of oil supply should be sufficient to

ensure bearing lubrication until the machine comes to a complete stop.

Typical lube oil rundown or coast-down tanks incorporate (1) an orifice, (2) check

valve, and (3) rapid fill valve. During normal operation of the machinery unit, a

trickle of lube oil flows through the orifice into the tank, and returns through a top-

mounted nozzle back to the reservoir. When the static pressure in the elevated tank

exceeds the pressure in (4) the supply header, lube oil flows down through the check