Page 54 - Improving Machinery Reliability

P. 54

26 hnprovirig Mcrchinery Reliability

RETURN LINES

TO RESERVOIR

MAIN STANDBY EMERGENCY

PUMP PUMP

4 4 4

f--

(SEE NOTES 7 AND 8) 4c-W AUXILIARY PUMP SUCTION

(TYPICAL: SEE NOTE 4)

(SEE NOTE 5) -

$71

PUMP SUCTION

FROM

RESERVOIR

NOTES: the main, standby. or emergency pump.

1. Option A-20a: Alarm switches arcomitled if(a) the running signal 5. Suclion V~~YCI are omitted for pumps submerged in the rc6crvotc.

is taken from the molorslarlcr or (b) an alarm swilclt is on the turbine 6. The pressure-regulating (relic0 valve is omitled lor centrilugal

driver. pumps.

2. Oplion A-20b The purchaser may specify a bypass valve to ~1~1. 7. For centrifugal pumps., Ihe line slrainers are omillcd and iempo.

3. Oplian A.2Oc: The purchaser may rpecily an emergency pump. rary screen8 are provided.

4. Oplion A-2Od: Far psilive displacement pumps. the purchaser 8. A basket-type screen shall be used instead 01 a lint slramer for the

may specify an auxiliary emergency suclion line from the reservoir 10 suction of pumps submcrged in the reservoir.

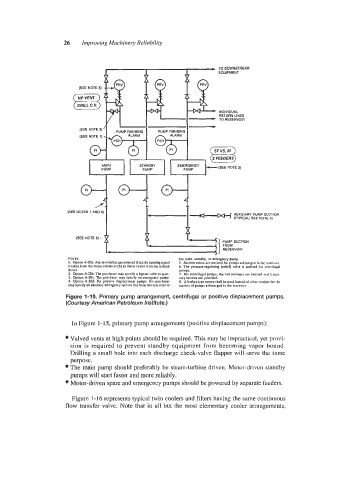

Figure 1-15. Primary pump arrangement, centrifugal or positive displacement pumps.

(Courtesy American Petroleum Institute.)

In Figure 1 - 15, primary pump arrangements (positive displacement pumps):

Valved vents at high points should be required. This may be impractical, yet provi-

sion is required to prevent standby equipment from becoming vapor bound.

Drilling a small hole into each discharge check-valve flapper will serve the same

purpose.

The main pump should preferably be steam-turbine driven. Motor-driven standby

pumps will start faster and more reliably.

Motor-driven spare and emergency pumps should be powered by separate feeders.

Figure 1-16 represents typical twin coolers and filters having the same continuous

flow transfer valve. Note that in all but the most elementary cooler arrangements,