Page 53 - Improving Machinery Reliability

P. 53

Requirements Specification 25

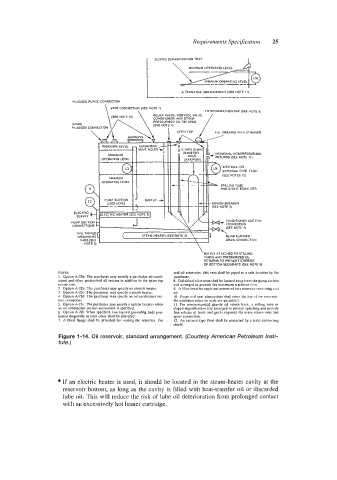

I SLOPED DEGASIFICATION TRAY

MAXIMUM OPERATING LEVEL

I -- -- -

ALTERNATIVE ARRANGEMENT [SEE NOTE It)

PLUGGED PURGE CONNECTION

EN1 CONNECT10

FILTER-BREATHER CAP (SEE NOTE 9)

LIEF VALVE, CONTROL VAL

NDITIONER. AND OTHER

ED OIL RETURNS

SPARE

PLUGGED CONNECT1

PENING WITH STRAINER

DUAL NONPRESSURIZED

EXTERNAL-TYPE FLOAT

(SEE NOTES 121

STILLING TUBE

AND STATIC EOUALIZER

9 SIPHON BREAKER

ELECTRIC 5-

SUPPLY

PUMP SUCTION

CONNECTIONS

TWO TAPPED

GROUNDING STEAM HEATER (SEE NOTE 31 BLIND-FLANGED

PADS (SEE \ DRAIN CONNECTION

NOTE 61

'BAFFLE ATTAChED TO ST.LLlhG

TLBES AND PRESSURiZED O.L

RETURhS TO PREVEhT STlflR NG

OF BOTTOM SEO.MENTS [SEE NOTE 61

NOTES: seal-oil resewoirs, this vent shall be piped to a sale localion by Ihe

I Option A-22a: The purchaser may spcciiy a particular oil condi. purchaser.

!loner and other pressurized oil returns in addition IO the spare top 8. Individual oil relurns shall be located away from the pump suchon

connection. and arranged 10 provide the maximum residence lime

.

.

2 Option A.22b. The purchaser may speciiy an electric healer. 9. A filtcr.bredlhcr capis no1 permitied on B reservuir contdning 5rdl

3 Opiton A-22c: The purchaser may specify a steam heater. ail.

4. Option A-22d: The purchaser may specify an oil conditioner WE- IO. Purge and vcnl connections shall enter Ihe lop ')I the iexrroii

lion connection. No exlension tubcr or seals are pcrmitlcd.

5. Option A-22e. The purchaser may specify P siphon breaker when II. For nonpresrurired gravbly oil return liner. a rlilltng tube or

an oil condilioner suction conneclion is spccificd. rlopcd degasilkation m y arranged IO prcvenl splashing and provide

6. Option A-22f: When specified. lwo lapped grounding pads posi. free relcaic of luam and gar is required for cvcry return inlet and

rioned diagonally to each oiher shall be provided. spare connection.

7 A blind flange shall be provided lor venling the reservoir. Far 12. An internal-lype nodl shall be protected by a siatic-cvnducling

shield.

Figure 1-14. Oil reservoir, standard arrangement. (Courtesy American Petroleum Insti-

tute.)

If an electric heater is used, it should be located in the steam-heater cavity at the

reservoir bottom, as long as the cavity is filled with heat-transfer oil or discarded

lube oil. This will reduce the risk of lube oil deterioration from prolonged contact

with an excessively hot heater cartridge.