Page 239 - Industrial Cutting of Textile Materials

P. 239

226 Industrial Cutting of Textile Materials

of a single garment, with very different shapes and sizes, have to be laid in a marker.

Conventional (overall) markers are also created automated way using specialized

marker-making software for checked fabrics.

14.3.1 An initial maker

To simplify the making of sectioned markers, those pattern pieces that need to be

grouped in sections when laid directly onto the fabric are produced from an initial

marker printed on paper (see Section 14.2.2).

14.3.2 The coordination of pattern

The information about the placement of patterns on fabrics is obtained from the style

sample and its technical documentation. The largest, most important pattern pieces

are placed in the marker first. Their centre lines have to be placed on the centre stripe

of the checks (see Fig. 14.19A) or on the centre of their centre space as shown in

Fig. 14.19B.

All body pattern pieces are placed in a marker aligning the pattern in a horizontal

direction and, in some cases, both a horizontal and vertical directions. Figs 14.20 and

14.21 show examples of components aligned in a horizontal direction. Those patterns

(A) (B)

Fig. 14.19 Placement of the centre line of a back on the centre stripe (A) or on the centre of

the centre space (B).

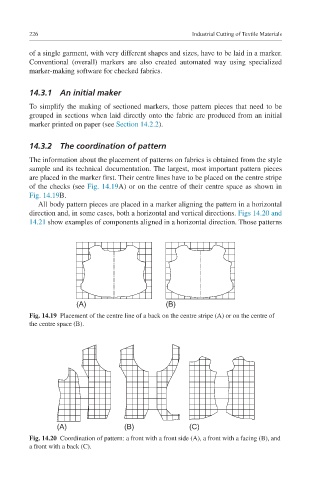

(A) (B) (C)

Fig. 14.20 Coordination of pattern: a front with a front side (A), a front with a facing (B), and

a front with a back (C).