Page 263 - Industrial Cutting of Textile Materials

P. 263

250 Industrial Cutting of Textile Materials

15.3.1 Formation of a multi-ply spread matching fabric pattern

Multi-ply spreads are performed manually, matching the pattern in all fabric plies.

Instead of separate metal needles put on the traditional spreading table, specialized

needle tables and overhead projectors can be used to coordinate pattern in between

fabric plies.

15.3.1.1 Pin table (needle table)

1

5

Companies Morgan Tecnica (Italy), Veith System (Germany), and Caron

6

Technology (Italy) have developed special pin tables to ease pattern matching in

between fabric plies.

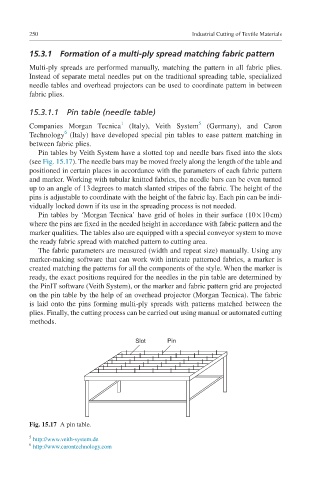

Pin tables by Veith System have a slotted top and needle bars fixed into the slots

(see Fig. 15.17). The needle bars may be moved freely along the length of the table and

positioned in certain places in accordance with the parameters of each fabric pattern

and marker. Working with tubular knitted fabrics, the needle bars can be even turned

up to an angle of 13 degrees to match slanted stripes of the fabric. The height of the

pins is adjustable to coordinate with the height of the fabric lay. Each pin can be indi-

vidually locked down if its use in the spreading process is not needed.

Pin tables by ‘Morgan Tecnica’ have grid of holes in their surface (10 × 10 cm)

where the pins are fixed in the needed height in accordance with fabric pattern and the

marker qualities. The tables also are equipped with a special conveyor system to move

the ready fabric spread with matched pattern to cutting area.

The fabric parameters are measured (width and repeat size) manually. Using any

marker-making software that can work with intricate patterned fabrics, a marker is

created matching the patterns for all the components of the style. When the marker is

ready, the exact positions required for the needles in the pin table are determined by

the PinIT software (Veith System), or the marker and fabric pattern grid are projected

on the pin table by the help of an overhead projector (Morgan Tecnica). The fabric

is laid onto the pins forming multi-ply spreads with patterns matched between the

plies. Finally, the cutting process can be carried out using manual or automated cutting

methods.

Slot Pin

Fig. 15.17 A pin table.

5 http://www.veith-system.de

6 http://www.carontechnology.com