Page 260 - Industrial Cutting of Textile Materials

P. 260

Multi-ply processing of styles from intricate pattern textiles 247

15.2.2.2 The spreading of components onto metal pins

The second spreading of components onto metal pins is used in the following situa-

tions: for materials with slippery surfaces, for lays with many plies, for components

that demand very precise pattern matching on their main construction points, and for

fusible components. The pins are placed on a spreading table with an underlay pa-

per (see Section 4.2.2) on top so that the pins penetrate the paper (see Chapter 16,

Fig. 16.4). Because of its firm structure, the paper keeps the pins in a fixed position

during the subsequent spreading process. Alternatively, a special spreading table may

be used that has pins inserted into its surface at intervals along its length and width

(see Section 15.3.1.1). The number and placement of the pins depend on the fabric

pattern and the size of the components:

Striped and checked fabrics: each ply of fabric is placed onto the pins at a specific pattern

●

line. For small components, two or three pins are used (see Figs 15.11 and 15.12). When

spreading large components, the pins are placed in the shape of a rectangle or in a single line

(see Figs 15.13 and 15.14).

Fabrics with motif and border patterns: it is preferable to place the pins in the most import-

●

ant points of the pattern on lines corresponding to the directions of the fabric warp or weft

(see Fig. 15.15; pins 1 and 2). The fabric is less elastic in these directions; therefore, the

coordination of the patterns with the pins will be easier and more accurate.

– Placement of pins

(A) (B)

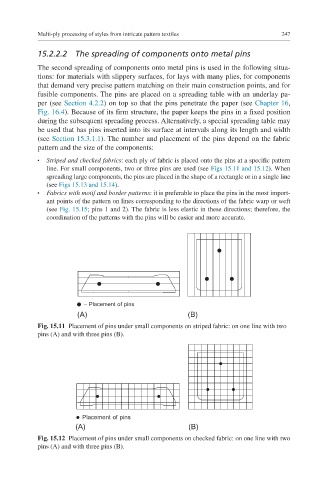

Fig. 15.11 Placement of pins under small components on striped fabric: on one line with two

pins (A) and with three pins (B).

Placement of pins

(A) (B)

Fig. 15.12 Placement of pins under small components on checked fabric: on one line with two

pins (A) and with three pins (B).