Page 255 - Industrial Cutting of Textile Materials

P. 255

242 Industrial Cutting of Textile Materials

Fig. 15.1 Short spread of striped knitted fabric performed in one work step.

15.2.1 The first spreading and rough cutting

The first spreading operation can be performed manually or in an automated way by

laying down plies of fabric on top of each other, ensuring that each ply is of sufficient

length and that the pattern in the fabric between the plies is aligned. Longer lays make

the matching of the patterns across the plies more complex.

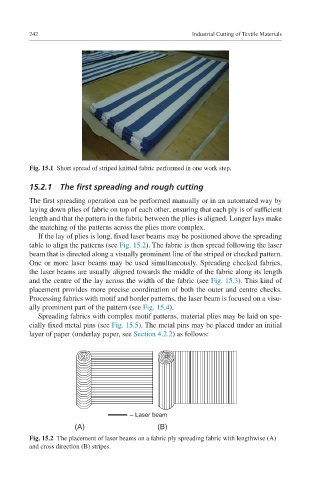

If the lay of plies is long, fixed laser beams may be positioned above the spreading

table to align the patterns (see Fig. 15.2). The fabric is then spread following the laser

beam that is directed along a visually prominent line of the striped or checked pattern.

One or more laser beams may be used simultaneously. Spreading checked fabrics,

the laser beams are usually aligned towards the middle of the fabric along its length

and the centre of the lay across the width of the fabric (see Fig. 15.3). This kind of

placement provides more precise coordination of both the outer and centre checks.

Processing fabrics with motif and border patterns, the laser beam is focused on a visu-

ally prominent part of the pattern (see Fig. 15.4).

Spreading fabrics with complex motif patterns, material plies may be laid on spe-

cially fixed metal pins (see Fig. 15.5). The metal pins may be placed under an initial

layer of paper (underlay paper, see Section 4.2.2) as follows:

– Laser beam

(A) (B)

Fig. 15.2 The placement of laser beams on a fabric ply spreading fabric with lengthwise (A)

and cross direction (B) stripes.