Page 259 - Industrial Cutting of Textile Materials

P. 259

246 Industrial Cutting of Textile Materials

shape of the roughly cut components better than fabric and can be used to ensure

the correct positioning of components during the second spreading. After the second

spreading, the components are cut precisely using a band-knife machine.

15.2.2.1 The alignment of patterns by one precisely cut edge

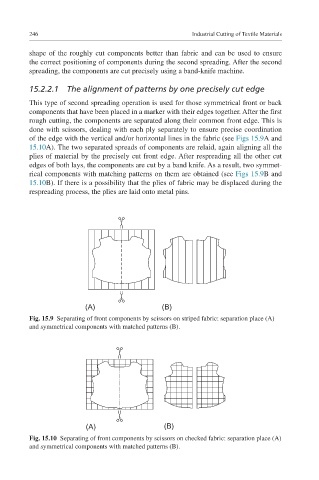

This type of second spreading operation is used for those symmetrical front or back

components that have been placed in a marker with their edges together. After the first

rough cutting, the components are separated along their common front edge. This is

done with scissors, dealing with each ply separately to ensure precise coordination

of the edge with the vertical and/or horizontal lines in the fabric (see Figs 15.9A and

15.10A). The two separated spreads of components are relaid, again aligning all the

plies of material by the precisely cut front edge. After respreading all the other cut

edges of both lays, the components are cut by a band knife. As a result, two symmet-

rical components with matching patterns on them are obtained (see Figs 15.9B and

15.10B). If there is a possibility that the plies of fabric may be displaced during the

respreading process, the plies are laid onto metal pins.

(A) (B)

Fig. 15.9 Separating of front components by scissors on striped fabric: separation place (A)

and symmetrical components with matched patterns (B).

(A) (B)

Fig. 15.10 Separating of front components by scissors on checked fabric: separation place (A)

and symmetrical components with matched patterns (B).