Page 261 - Industrial Cutting of Textile Materials

P. 261

248 Industrial Cutting of Textile Materials

– Placement of pins

(A) (B)

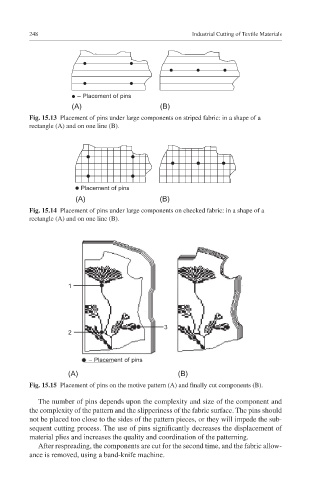

Fig. 15.13 Placement of pins under large components on striped fabric: in a shape of a

rectangle (A) and on one line (B).

Placement of pins

(A) (B)

Fig. 15.14 Placement of pins under large components on checked fabric: in a shape of a

rectangle (A) and on one line (B).

1

3

2

– Placement of pins

(A) (B)

Fig. 15.15 Placement of pins on the motive pattern (A) and finally cut components (B).

The number of pins depends upon the complexity and size of the component and

the complexity of the pattern and the slipperiness of the fabric surface. The pins should

not be placed too close to the sides of the pattern pieces, or they will impede the sub-

sequent cutting process. The use of pins significantly decreases the displacement of

material plies and increases the quality and coordination of the patterning.

After respreading, the components are cut for the second time, and the fabric allow-

ance is removed, using a band-knife machine.