Page 58 - Industrial Cutting of Textile Materials

P. 58

Principles and methods of textile spreading 45

52 A 38 B 38 B 52 A

52 A 52 A 38 B

52 A 52 A 38 B

52 A 38 B 38 B 52 A 52 A 38 B 38 B 52 A

52 A 52 A 52 A 52 A 52 A 52 A

38 B 52 A 52 A 38 B 52 A 38 B 52 A 52 A 38 B 52 A

52 A

52 A

38 B 52 38 B 38 38 B 38 B 52 38 B 38 38 B

38 B 52 38 B 38 B 38 38 B 52 38 B 38 B 38

52 A 52 A 52 A

52 A 38 B 38 B 52 A 38 B 38 B

– Component with a fault —A fault

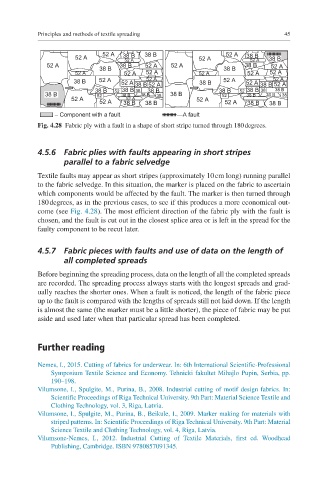

Fig. 4.28 Fabric ply with a fault in a shape of short stripe turned through 180 degrees.

4.5.6 Fabric plies with faults appearing in short stripes

parallel to a fabric selvedge

Textile faults may appear as short stripes (approximately 10 cm long) running parallel

to the fabric selvedge. In this situation, the marker is placed on the fabric to ascertain

which components would be affected by the fault. The marker is then turned through

180 degrees, as in the previous cases, to see if this produces a more economical out-

come (see Fig. 4.28). The most efficient direction of the fabric ply with the fault is

chosen, and the fault is cut out in the closest splice area or is left in the spread for the

faulty component to be recut later.

4.5.7 Fabric pieces with faults and use of data on the length of

all completed spreads

Before beginning the spreading process, data on the length of all the completed spreads

are recorded. The spreading process always starts with the longest spreads and grad-

ually reaches the shorter ones. When a fault is noticed, the length of the fabric piece

up to the fault is compared with the lengths of spreads still not laid down. If the length

is almost the same (the marker must be a little shorter), the piece of fabric may be put

aside and used later when that particular spread has been completed.

Further reading

Nemes, I., 2015. Cutting of fabrics for underwear. In: 6th International Scientific-Professional

Symposium Textile Science and Economy. Tehnicki fakultet Mihajlo Pupin, Serbia, pp.

190–198.

Vilumsone, I., Spulgite, M., Purina, B., 2008. Industrial cutting of motif design fabrics. In:

Scientific Proceedings of Riga Technical University. 9th Part: Material Science Textile and

Clothing Technology, vol. 3, Riga, Latvia.

Vilumsone, I., Spulgite, M., Purina, B., Beikule, I., 2009. Marker making for materials with

striped patterns. In: Scientific Proceedings of Riga Technical University. 9th Part: Material

Science Textile and Clothing Technology, vol. 4, Riga, Latvia.

Vilumsone-Nemes, I., 2012. Industrial Cutting of Textile Materials, first ed. Woodhead

Publishing, Cambridge. ISBN 9780857091345.