Page 55 - Industrial Cutting of Textile Materials

P. 55

42 Industrial Cutting of Textile Materials

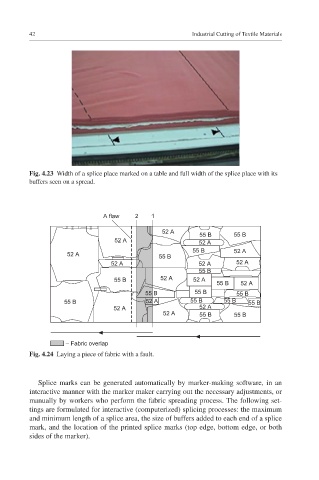

Fig. 4.23 Width of a splice place marked on a table and full width of the splice place with its

buffers seen on a spread.

A flaw 2 1

52 A 55 B 55 B

52 A 52 A

55 B 52 A

52 A 55 B

52 A 52 A 52 A

55 B

55 B 52 A 52 A

55 B 52 A

55 B 55 B 55 B

55 B 52 A 55 B 55 B 55 B

52 A 52 A

52 A 55 B 55 B

– Fabric overlap

Fig. 4.24 Laying a piece of fabric with a fault.

Splice marks can be generated automatically by marker-making software, in an

interactive manner with the marker maker carrying out the necessary adjustments, or

manually by workers who perform the fabric spreading process. The following set-

tings are formulated for interactive (computerized) splicing processes: the maximum

and minimum length of a splice area, the size of buffers added to each end of a splice

mark, and the location of the printed splice marks (top edge, bottom edge, or both

sides of the marker).