Page 52 - Industrial Cutting of Textile Materials

P. 52

Principles and methods of textile spreading 39

44 44 44 36

44 36 36

44

44

44 36 36

44 44

36

44 44 36

36 36 36 36

44 44 36

36

44

44 44 36 36

36

44 36 36

44 44 44 36

36

Size 44 Size 36

Fabric

plies

Fig. 4.17 Spreading of a step kind spread.

Marker

Fabric plies

Spreading table

Fig. 4.18 Marker placed on a step kind spread.

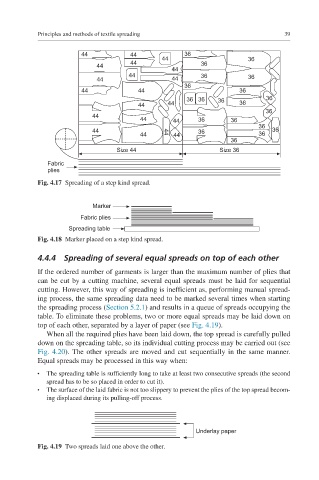

4.4.4 Spreading of several equal spreads on top of each other

If the ordered number of garments is larger than the maximum number of plies that

can be cut by a cutting machine, several equal spreads must be laid for sequential

cutting. However, this way of spreading is inefficient as, performing manual spread-

ing process, the same spreading data need to be marked several times when starting

the spreading process (Section 5.2.1) and results in a queue of spreads occupying the

table. To eliminate these problems, two or more equal spreads may be laid down on

top of each other, separated by a layer of paper (see Fig. 4.19).

When all the required plies have been laid down, the top spread is carefully pulled

down on the spreading table, so its individual cutting process may be carried out (see

Fig. 4.20). The other spreads are moved and cut sequentially in the same manner.

Equal spreads may be processed in this way when:

The spreading table is sufficiently long to take at least two consecutive spreads (the second

●

spread has to be so placed in order to cut it).

The surface of the laid fabric is not too slippery to prevent the plies of the top spread becom-

●

ing displaced during its pulling-off process.

Underlay paper

Fig. 4.19 Two spreads laid one above the other.