Page 669 - Industrial Power Engineering and Applications Handbook

P. 669

19/634 Industrial Power Engineering and Applications Handbook

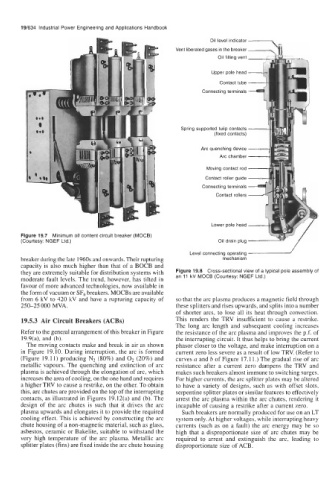

Oil level indicator

Vent liberated gases in the breaker

Oil filling vent

Upper pole head

Contact tube

Connecting terminals

Spring supported tulip contacts

(fixed contacts)

Arc quenching device

Arc chamber

Moving contact rod

Contact roller guide

Connecting terminals

Contact rollers

Lower pole head

Figure 19.7 Minimum oil content circuit breaker (MOCB)

(Courtesy: NGEF Ltd.) Oil drain plug

Level connecting operating

breaker during the late 1960s and onwards. Their rupturing mechanism

capacity is also much higher than that of a BOCB and

they are extremely suitable for distribution systems with Figure 19.8 Cross-sectional view of a typical pole assembly of

moderate fault levels. The trend, however, has tilted in an 11 kV MOCB (Courtesy: NGEF Ltd.)

favour of more advanced technologies, now available in

the form of vacuum or SF, breakers. MOCBs are available

from 6 kV to 420 kV and have a rupturing capacity of so that the arc plasma produces a magnetic field through

250-25 000 MVA. these splitters and rises upwards, and splits into a number

of shorter arcs, to lose all its heat through convection.

19.5.3 Air Circuit Breakers (ACBs) This renders the TRV insufficient to cause a restrike.

The long arc length and subsequent cooling increases

Refer to the general arrangement of this breaker in Figure the resistance of the arc plasma and improves the p.f. of

19.9(a), and (b). the interrupting circuit. It thus helps to bring the current

The moving contacts make and break in air as shown phasor closer to the voltage, and make interruption on a

in Figure 19.10. During interruption, the arc is formed current zero less severe as a result of low TRV. (Refer to

(Figure 19.11) producing N2 (80%) and O2 (20%) and curves a and b of Figure 17.1 1 .) The gradual rise of arc

metallic vapours. The quenching and extinction of arc resistance after a current zero dampens the TRV and

plasma is achieved through the elongation of arc, which makes such breakers almost immune to switching surges.

increases the area of cooling, on the one hand and requires For higher currents, the arc splitter plates may be altered

a higher TRV to cause a restrike, on the other. To obtain to have a variety of designs, such as with offset slots,

this, arc chutes are provided on the top of the interrupting serpentine splitter plates or similar features to effectively

contacts, as illustrated in Figures 19.12(a) and (b). The arrest the arc plasma within the arc chutes, rendering it

design of the arc chutes is such that it drives the arc incapable of causing a restrike after a current zero.

plasma upwards and elongates it to provide the required Such breakers are normally produced for use on an LT

cooling effect. This is achieved by constructing the arc system only. At higher voltages, while interrupting heavy

chute housing of a non-magnetic material, such as glass, currents (such as on a fault) the arc energy may be so

asbestos, ceramic or Bakelite, suitable to withstand the high that a disproportionate size of arc chutes may be

very high temperature of the arc plasma. Metallic arc required to arrest and extinguish the arc, leading to

splitter plates (fins) are fixed inside the arc chute housing disproportionate size of ACB.