Page 680 - Industrial Power Engineering and Applications Handbook

P. 680

Circuit interruDters 19/645

Fixed contact stem

1 Fixed terminal pad

Met!t;ng

~

Glass ceramic

relay chamber

Explosion covers

Glass ceramic

Metallic bellows

Moving contact

Moving contact

stem

~~

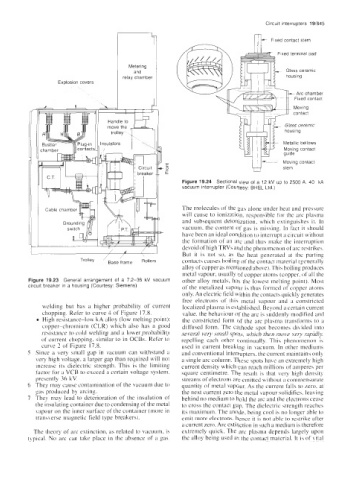

Figure 19.24 Sectional view of a 12 kV up to 2500 A. 40 kA

vacuum interrupter (Courtesy: BHEL Ltd.)

The molecules of the gas alone under heat and pressure

will cause to ionization. responsible for the arc plasma

and subsequent deionization, which extinguishes it. In

vacuum. the content of gas is missing. In fact it should

have been an ideal condition to interrupt a circuit without

the formation of an arc and thus make the interruption

devoid of high TRVs and the phenomenon of arc restrikes.

But it is not so, as the heat generated at the parting

contacts causes boiling of the contact material (generally

alloy of copper as mentioned above). This boiling produces

metal vapour, usually of copper atoms (copper, of all the

Figure 19.23 General arrangement of a 7.2-36 kV vacuum other alloy metals, has the lowest melting point). Most

circuit breaker in a housing (Courtesy: Siemens) of the metalized vapour is thus formed of copper atoms

only. An electric field within the contacts quickly generates

free electrons of this metal vapour and a constricted

welding but has a higher probability of current localized plasma is established. Beyond a certain current

chopping. Refer to curve 4 of Figure 17.8. value, the behaviour of the arc is suddenly modified and

High resistance-low kA alloy (low melting point): the constricted form of the arc plasma transforms to a

copper-chromium (CLR) which also has a good diffused form. The cathode spot becomes di\ided into

resistance to cold welding and a lower probability several very small spots, which then move very rapidly.

of current chopping, similar to in OCBs. Refer to repelling each other continually. This phenomenon is

curve 2 of Figure 17.8. used in current breaking in vacuum. In other mediums

5 Since a very small gap in vacuum can withstand a and conventional interrupters. the current maintains only

xry high voltage, a larger gap than required will not a single arc column. These spots have an extremely high

increase its dielectric strength. This is the limiting current density which can reach millions of amperes per

factor for a VCB to exceed a certain voltage system, square centimetre. The result is that very high density

presently 36 kV. streams of electrons are emitted without a commensurate

6 They may cause contamination of the vacuum due to quantity of metal vapour. As the current falls to zero, at

cas produced by arcing. the next current zero the metal vapour solidifies. leaving

7 They may lead to deterioration of the insulation of behind no medium to hold the arc and the electrons cease

the insulating container due to condensing ofthe metal to cross the contact gap. The dielectric strength reaches

vapour on the inner surface of the container (more in its maximum. The anode. being cool is no longer able to

trans\erse magnetic field type breakers). emit more electrons, hence it is not able to restrike after

a current zero. Arc extinction in such a medium is therefore

The theory of arc extinction, as related to vacuum, is extremely quick. The arc plasma depends largely upon

typical. No arc can take place in the absence of a gas. the alloy being used as the contact matcrial. It i$ of vital