Page 676 - Industrial Power Engineering and Applications Handbook

P. 676

Circuit interrupters 191641

The events are so fine-tuned and the size of chamber,

pressure of gas, travel, distance of the moving contact

and the size of blast nozzle so designed and adjusted that

a near-strike-free interruption can be achieved for low

reactive currents (inductive or capacitive) as well as full-

load and very heavy fault currents. The advance com-

pression of gas through the movement of main contact

plays an important role by storing a part of the gas even

before opening of the arcing contacts.

At high instantaneous currents the arc may occupy

most of the contact area between the arcing contacts and

may impede the flow of gas through the arc plasma. This

phenomenon is termed the clogging effect, but it assists

arc extinction in the following manner.

The gas around the arc plasma takes away a part of its

heat by radiation. At high temperatures, the gas loses its

specific gravity, becomes light weight and diminishes in

momentum (- mu2). As a result, the gas is rendered

incapable of penetrating through the arc plasma to quench

it. The flow of gas through the thick of the arc plasma is

thus impeded.

As the moving contact moves away, so the arc plasma

elongates, losing its initial intensity, and as it approaches

the current zero, it loses the most of it. The gas, on the

other hand, cools and regains its lost mass, while its

pressure in the chamber continues to build to its optimum

level, making it more capable of extinguishing a less

severe arc plasma. The interrupter can thus be adjusted

to blow out the arc at the first current zero, while clearing

heavy to very heavy fault currents.

Similarly, at lower currents, the volume of arc plasma

is too small (- Z2) and so is the clogging effect. The

pressure and volume of the quenching gas can be adjusted

to interrupt the current now also at current zero. All these

adjustments are pre-set and sealed by the manu-facturer.

Since the arc extinction technique is highly effective

and quick and occurs when the arcing contact is still

moving, arc length and hence contact travel, can be

reduced as can the arc energy and the excessive heating

as well as erosion of the arcing contacts. An extended

contact life can thus be achieved by this technique.

In lower voltage ratings, as noted above, the puffer

technique is quite prevalent and is adopted by all leading

manufacturers. For constructional details and more

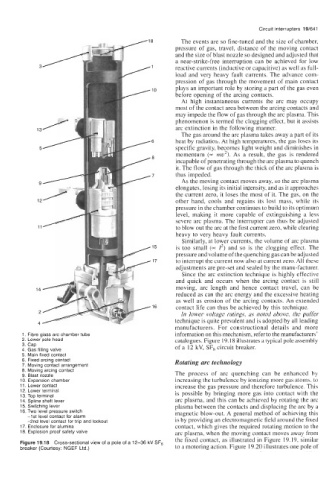

1. Fibre glass arc chamber tube information on this mechanism, refer to the manufacturers’

2. Lower pole head catalogues. Figure 19.18 illustrates a typical pole assembly

3. Cap of a 12 kV, SF6 circuit breaker.

4. Gas filling valve

5. Main fixed contact

6. Fixed arcing contact Rotating arc technology

7. Moving contact arrangement

8. Moving arcing contact The process of arc quenching can be enhanced by

9. Blast nozzle

IO. Expansion chamber increasing the turbulence by ionizing more gas atoms, to

11. Lower contact increase the gas pressure and therefore turbulence. This

12. Lower terminal is possible by bringing more gas into contact with the

13. Top terminal

14. Spline shaft lever arc plasma, and this can be achieved by rotating the arc

15. Switching lever plasma between the contacts and displacing the arc by a

16. Two level pressure switch magnetic blow-out. A general method of achieving this

-1 st level contact for alarm

-2nd level contact for trip and lockout is by providing an electromagnetic field around the fixed

17. Enclosure for alumina contact, which gives the required rotating motion to the

18. Explosion proof safety valve arc plasma, when the moving contact moves away from

the fixed contact, as illustrated in Figure 19.19, similar

Figure 19.18 Cross-sectional view of a pole of a 12-36 kV SF,

breaker (Courtesy: NGEF Ltd.) to a motoring action. Figure 19.20 illustrates one pole of