Page 679 - Industrial Power Engineering and Applications Handbook

P. 679

19/644 Industrial Power Engineering and Applications Handbook

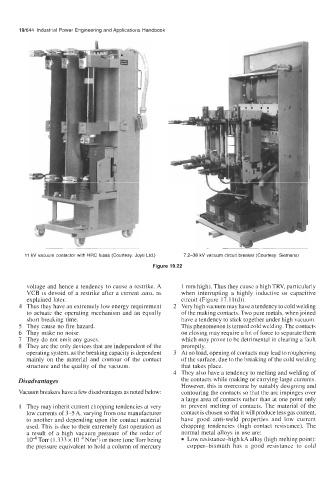

11 kV vacuum contactor with HRC fuses (Courtesy: Joyti Ltd.) 7.2-36 kV vacuum circuit breaker (Courtesy: Siemens)

Figure 19.22

voltage and hence a tendency to cause a restrike. A 1 mm high). Thus they cause a high TRV, particularly

VCB is devoid of a restrike after a current zero, as when interrupting a highly inductive or capacitive

explained later. circuit (Figure 17.1 l(d)).

Thus they have an extremely low energy requirement Very high vacuum may have a tendency to cold welding

to actuate the operating mechanism and an equally of the making contacts. Two pure metals, when joined

short breaking time. have a tendency to stick together under high vacuum.

They cause no fire hazard. This phenomenon is termed cold welding. The contacts

They make no noise. on closing may require a lot of force to separate them

They do not emit any gases. which may prove to be detrimental in clearing a fault

They are the only devices that are independent of the promptly.

operating system, as the breaking capacity is dependent At no load, opening of contacts may lead to roughening

mainly on the material and contour of the contact of the surface, due to the breaking of the cold welding

structure and the quality of the vacuum. that takes place.

They also have a tendency to melting and welding of

Disadvantages the contacts while making or carrying large currents.

However, this is overcome by suitably designing and

Vacuum breakers have a few disadvantages as noted below: contouring the contacts so that the arc impinges over

a large area of contacts rather than at one point only

1 They may inherit current chopping tendencies at very to prevent melting of contacts. The material of the

low currents of 3-5 A, varying from one manufacturer contact is chosen so that it will produce less gas content,

to another and depending upon the contact material have good anti-weld properties and low current

used. This is due to their extremely fast operation as chopping tendencies (high contact resistance). The

a result of a high vacuum pressure of the order of normal metal alloys in use are:

Torr (1.333 x lo4 N/m2) or more (one Torr being Low resistance-high kA alloy (high melting point):

the pressure equivalent to hold a column of mercury copper-bismuth has a good resistance to cold