Page 84 - Industrial Power Engineering and Applications Handbook

P. 84

Duties of induction motors 3/65

(One cycle) on its speed-torque curve, the motor will not drop its speed

substantially and cause high slip losses.

Note For such duties, the starting heat is kept as low as

possible by suitable rotor design to eliminate the effect of

frequent starts and stops. The margin for starting heat and

braking heat should be taken into account if these are

considerable. The manufacturer is a better guide for

suggestions here.

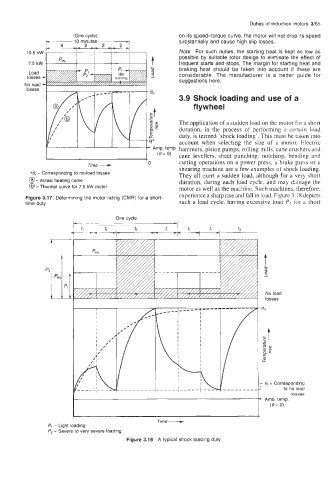

3.9 Shock loading and use of a

flywheel

The application of a sudden load on the motor for short

duration, in the process of performing a certain load

duty, is termed 'shock loading'. This must be taken into

account when selecting the size of a motor. Electric

mp. temp hammers, piston pumps, rolling mills, cane crushers and

(e = O) cane levellers, sheet punching, notching, bending and

Time + 0 cutting operations on a power press, a brake press or a

shearing machine are a few examples of shock loading.

*e, - Corresponding to no-load losses They all exert a sudden load. although for a very short

0- Actual heating curve duration, during each load cycle, and may damage the

@ - Thermal curve for 7.5 kW motor motor as well as the machine. Such machines. therefore,

Figure 3.17 the motor rat,ng (CMR) for a short- experience a sharp rise and fall in load. Figure 3.18 depicts

time duty wch a load cycle, having excessive load P2 for d short

T

t

p3

No load

i losses

= Corresponding

to no load

losses

Time - r

P, - Light loading

P2 - Severe to very severe loading

Figure 3.18 A typical shock loading duty