Page 453 - Industrial Wastewater Treatment, Recycling and Reuse

P. 453

424 Industrial Wastewater Treatment, Recycling, and Reuse

800

Feed COD

700 Bioreactor COD

Permeate COD

600

500

COD (mg/L) 400

300

200

100

0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85

Days of operation

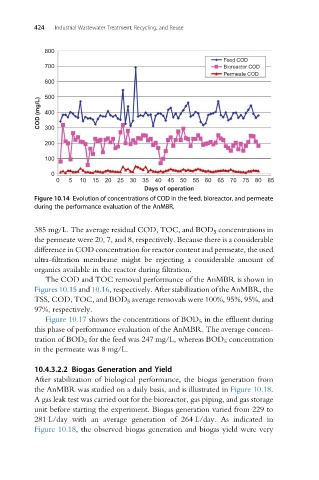

Figure 10.14 Evolution of concentrations of COD in the feed, bioreactor, and permeate

during the performance evaluation of the AnMBR.

385 mg/L. The average residual COD, TOC, and BOD 5 concentrations in

the permeate were 20, 7, and 8, respectively. Because there is a considerable

difference in COD concentration for reactor content and permeate, the used

ultra-filtration membrane might be rejecting a considerable amount of

organics available in the reactor during filtration.

The COD and TOC removal performance of the AnMBR is shown in

Figures 10.15 and 10.16, respectively. After stabilization of the AnMBR, the

TSS, COD, TOC, and BOD 5 average removals were 100%, 95%, 95%, and

97%, respectively.

Figure 10.17 shows the concentrations of BOD 5 in the effluent during

this phase of performance evaluation of the AnMBR. The average concen-

tration of BOD 5 for the feed was 247 mg/L, whereas BOD 5 concentration

in the permeate was 8 mg/L.

10.4.3.2.2 Biogas Generation and Yield

After stabilization of biological performance, the biogas generation from

the AnMBR was studied on a daily basis, and is illustrated in Figure 10.18.

A gas leak test was carried out for the bioreactor, gas piping, and gas storage

unit before starting the experiment. Biogas generation varied from 229 to

281 L/day with an average generation of 264 L/day. As indicated in

Figure 10.18, the observed biogas generation and biogas yield were very