Page 457 - Industrial Wastewater Treatment, Recycling and Reuse

P. 457

Application of Anaerobic Membrane Bioreactor 427

300 0.60

250 0.50

Biogas generated (L/day) 150 Biogas generated 0.30 Biogas yield (m 3 /kg COD removed)

0.40

200

Biogas yield

0.20

100

50 0.10

0 0.00

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85

Days of operation

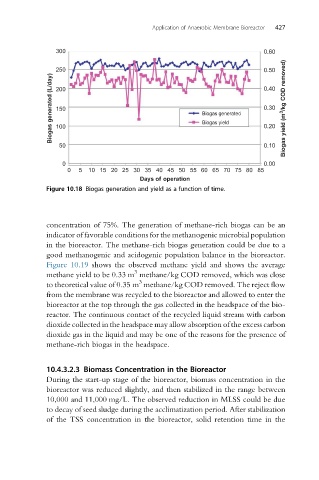

Figure 10.18 Biogas generation and yield as a function of time.

concentration of 75%. The generation of methane-rich biogas can be an

indicator of favorable conditions for the methanogenic microbial population

in the bioreactor. The methane-rich biogas generation could be due to a

good methanogenic and acidogenic population balance in the bioreactor.

Figure 10.19 shows the observed methane yield and shows the average

3

methane yield to be 0.33 m methane/kg COD removed, which was close

3

to theoretical value of 0.35 m methane/kg COD removed. The reject flow

from the membrane was recycled to the bioreactor and allowed to enter the

bioreactor at the top through the gas collected in the headspace of the bio-

reactor. The continuous contact of the recycled liquid stream with carbon

dioxide collected in the headspace may allow absorption of the excess carbon

dioxide gas in the liquid and may be one of the reasons for the presence of

methane-rich biogas in the headspace.

10.4.3.2.3 Biomass Concentration in the Bioreactor

During the start-up stage of the bioreactor, biomass concentration in the

bioreactor was reduced slightly, and then stabilized in the range between

10,000 and 11,000 mg/L. The observed reduction in MLSS could be due

to decay of seed sludge during the acclimatization period. After stabilization

of the TSS concentration in the bioreactor, solid retention time in the