Page 218 - Instrumentation Reference Book 3E

P. 218

Transmitter: a field-mounted device used to -

202 Microprocessor-based and intelligent transmitters

Secondary sensor: The sensor mounted adja- Differential

cent to the primary sensor to measure the phys- Pressure

characteristic of the primary sensor (e.g., the effect I I Temperature

ical parameter which adversely affects the basic

of temperature on a pressure sensor).

Pressure

sense a physical parameter (e.g., temperature) at

the point where it is mounted and to provide a Flow

signal in a 4-20mA circuit which is a function n (other than AP)

(usually proportional) of the parameter. I

Microprocessor-based transmitter: a transmitter Level

in which a microprocessor system is used to correct

non-linearity errors of the primary sensor through Density

interpolation of calibration data held in memory, or

to compensate for the effect of secondary influences E3 Analysis

on the primary sensor by incorporating a secondary

sensor adjacent to the primary sensor and interpol- Figure 13.5 Relative numbers of process transmitters.

ating stored calibration data for both the primary

and secondary sensors. the characteristic curves for various thermocou-

Intelligent transmitter: a transmitter in which ples, platinum resistance, and other temperature

the functions of a microprocessor system are detectors that have to be embedded in memory,

shared between: (i) deriving the primary measure- for interpolation by the microprocessor through-

ment signal; (ii) storing information regarding the out the selected range of the transmitter. For

transmitter itself, its application data, and its loca- pressure and differential pressure transmitters, it

tion; and (iii) managing a communication system is the calibration data for both the primary and

which enables two-way communication between secondary sensors that have to be embedded in

the transmitter and either an interface unit con- memory for interpolation by the microprocessor

nected at any access point in the measurement throughout the selected range of the transmitter.

loop or at the control room. Differential pressure transmitters are particularly

Smart transmitter: an intelligent transmitter important because about half of the level mea-

with simultaneous digital communication super- surements and about two-thirds of flow measure-

imposed over the analog signal, i.e., smart is a ments are based on this measurement, although

special case of intelligent. this latter proportion is declining.

Fieldbus network: a single communication The second important development arises from

medium such as a twisted pair of copper conduc- the potential benefits to be derived from being

tors, coaxial cable, etc., which carries information able to communicate with a remote instrument

such as address, control data, and process para- over the same network that carries the measure-

meter data between a number of transmitters, ment signal. Hitherto, in the process industries,

actuators, controllers, etc. instruments have been regarded as devices which

are located in remote positions and connected by

a twisted pair of wires to the point where the

13.3 Background information measurement signal is required. The technology

which enables two types of information to be

The range of microprocessor-based measuring communicated over the same pair of wires, with-

systems now in use covers a wide variety of appli- out mutual interference, has long been available

cations, but those which are smart or intelligent but only recently has it been applied and

have been developed specifically for use in the exploited for process measurements.

process industries and, in this chapter, consider- Having developed transmitters in which micro-

ation is restricted to this particular range. The processors are used to enhance the performance by

types and relative numbers of process measure- linearizing the basic sensor characteristic or com-

ments varies from one industry to another, but pensating for secondary influences, it is a logical

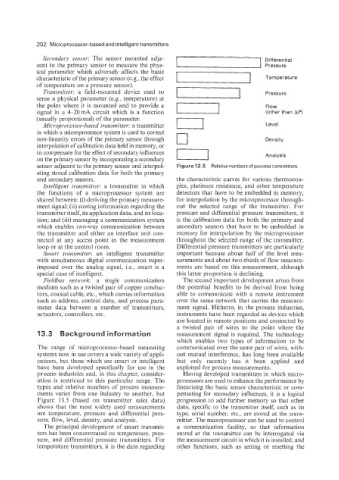

Figure 13.5 (based on transmitter sales data) progression to add further memory so that other

shows that the most widely used measurements data, specific to the transmitter itself, such as its

are temperature, pressure and differential pres- type, serial number, etc., are stored at the trans-

sure, flow, level, density, and analysis. mitter. The microprocessor can be used to control

The principal development of smart transmit- a communication facility, so that information

ters has been concentrated on temperature, pres- stored at the transmitter can be interrogated via

sure, and differential pressure transmitters. For the measurement circuit in which it is installed, and

temperature transmitters, it is the data regarding other functions, such as setting or resetting the