Page 24 - Instrumentation Reference Book 3E

P. 24

Fluid flow in closed pipes 9

1,3 Fluid flow in closed pipes

1.3.1 Differential-pressure devices

Differential pressure devices using a constriction

in the pipeline have been the most common tech-

nique for measuring fluid flow. Recently, other

devices have made substantial inroads in the basic

Mmrnum

measurement of fluids. Differential pressure is twice dro of

still a widely used technique, with even some

new devices that have been introduced in the

recent past. A recent estimate puts the use of Pressure

hole

differential pressure devices to measure flow in

the petrochemical industry at over 70 percent of

all flow devices. when d/D >O 67

As already shown in the derivation of Ber-

noulli's equation in the previous section, a con- @)

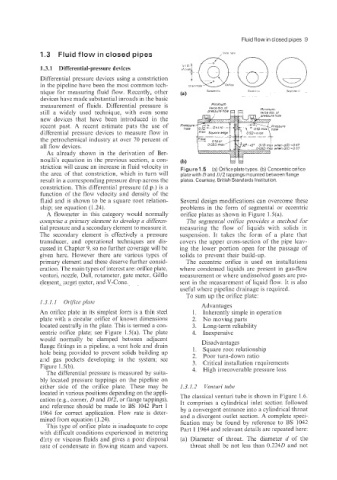

striction will cause an increase in fluid velocity in Figure 1.5 (a) Orifice platetypes. (b) Concentric orifice

the area of that constriction: which in turn will plate with D and 012 tappings mounted between flange

result in a corresponding pressure drop across the plates. Courtesy, British Standards Institution.

constriction. This differential pressure (d.p.) is a

function of the flow velocity and density of the

fluid and is shown to be a square root relation- Several design modifications can overcome these

ship; see equation (1.24). problems in the form of segmental or eccentric

A flowmeter in this category would normally orifice plates as shown in Figure lS(a).

comprise a primary element to develop a differen- The segmental orifice provides a method for

tial pressure and a secondary element to measure it. measuring the flow of liquids with solids in

The secolndary element is effectively a pressure suspension. It takes the form of a plate that

transducer, and operational techniques are dis- covers the upper cross-section of the pipe leav-

cussed in Chapter 9, so no further coverage will be ing the lower portion open for the passage of

given here. However there are various types of solids to prevent their build-up.

primary element and these deserve further consid- The eccentric orifice is used on installations

eration. The main types of interest are: orifice plate, where condensed liquids are present in gas-flow

venturi? nozzle, Dall, rotameter, gate meter, Gilflo measurement or where undissolved gases are pre-

element, iarget meter, and V-Cone. sent in the measurement of liquid flow. It is also

useful where pipeline drainage is required.

To sum up the orifice plate:

1.3.1.1 Orifice plate

Advantages

An orifice plate in its simplest form is a thin steel 1. Inherently simple in operation

plate with a circular orifice of known dimensions 2. No moving parts

located centrally in the plate. This is termed a con- 3. Long-term reliability

centric orifice plate; see Figure l.S(a). The plate 4. Inexpensive

would normally be clamped between adjacent Disadvantages

flange fittings in a pipeline, a vent hole and drain 1. Square root relationship

hole being provided to prevent solids building up 2. Poor turn-down ratio

arid gas pockets developing in the system; see 3. Critical installation requirements

Figure l.S(b). 4. High irrecoverable pressure loss

The differential pressure is measured by suita-

bly located pressure tappings on the pipeline on

either side of the orifice plate. These may be 1.3.1.2 Venturi tube

located in various positions depending on the appli-

cation (e.g., corner, D and 0/2, or flange tappings), The classical venturi tube is shown in Figure 1.6.

It comprises a cylindrical inlet section followed

and reference should be made to BS 1042 Part 1 by a convergent entrance into a cylindrical throat

1964 for correct application. Flow rate is deter- and a divergent outlet section. A complete speci-

mined from equation (1.24). fication may be found by reference to BS 1042

This type of orifice plate is inadequate to cope

with difficult conditions experienced in metering Part 1 1964 and relevant details are repeated here:

drty or viscous fluids and gives a poor disposal (a) Diameter of throat. The diameter d of the

rate of condensate in flowing steam and vapors. throat shall be not less than 0.2240 and not