Page 25 - Instrumentation Reference Book 3E

P. 25

10 Measurement of flow

Radius between To sum up the venturi tube:

zero ond I.80 Exit Advantages

i’

0.50 0.50

1 diometw 1. Simple in operation

05dJg

2. Low head loss

3. Tolerance of high solids content

4. Long-term reliability

5. No moving parts

Disadvantages

1. Expensive

2. Square root pressure-velocity relationship

Radius between zero and 55d

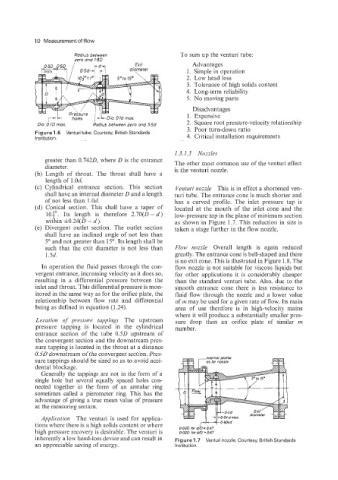

Figurel.6 Venturi tube. Courtesy, British Standards 3. Poor turn-down ratio

4. Critical installation requirements

Institution.

1.3.1.3 Nozzles

greater than 0.7420, where D is the entrance The other most common use of the venturi effect

diameter. is the venturi nozzle.

Length of throat. The throat shall have a

length of 1.0d.

Cylindrical entrance section. This section Venturi nozzle This is in effect a shortened ven-

shall have an internal diameter 0 and a length turi tube. The entrance cone is much shorter and

of not less than 1.0d. has a curved profile. The inlet pressure tap is

Conical section. This shall have a taper of located at the mouth of the inlet cone and the

lo$’,. Its length is therefore 2.70(0 - d) low-pressure tap in the plane of minimum section

within f0.24(D - d). as shown in Figure 1.7. This reduction in size is

Divergent outlet section. The outlet section taken a stage further in the flow nozzle.

shall have an inclined angle of not less than

5O and not greater than 15’. Its length shall be

such that the exit diameter is not less than Flow nozzle Overall length is again reduced

1 Sd. greatly. The entrance cone is bell-shaped and there

is no exit cone. This is illustrated in Figure 1.8. The

In operation the fluid passes through the con- flow nozzle is not suitable for viscous liquids but

vergent entrance, increasing velocity as it does so, for other applications it is considerably cheaper

resulting in a differential pressure between the than the standard venturi tube. Also, due to the

inlet and throat. This differential pressure is mon- smooth entrance cone there is less resistance to

itored in the same way as for the orifice plate, the fluid flow through the nozzle and a lower value

relationship between flow rate and differential of m may be used for a given rate of flow. Its main

being as defined in equation (1.24). area of use therefore is in high-velocity mains

where it will produce a substantially smaller pres-

Location of pressure tappings The upstream sure drop than an orifice plate of similar m

pressure tapping is located in the cylindrical number.

entrance section of the tube 0.5D upstream of

the convergent section and the downstream pres-

sure tapping is located in the throat at a distance

0.50 downstream of the convergent section. Pres-

sure tappings should be sized so as to avoid acci-

dental blockage.

Generally the tappings are not in the form of a

single hole but several equally spaced holes con-

nected together in the form of an annular ring

sometimes called a piezometer ring. This has the

advantage of giving a true mean value of pressure

at the measuring section.

Application The venturi is used for applica-

tions where there is a high solids content or where 0.030 for d/0 F 0 67

high pressure recovery is desirable. The venturi is 0020 fordD-067

inherently a low head-loss device and can result in Figure 1.7 Venturi nozzle Courtesy, British Standards

an appreciable saving of energy. Institution.