Page 28 - Instrumentation Reference Book 3E

P. 28

Fluid flow in closed pipes 13

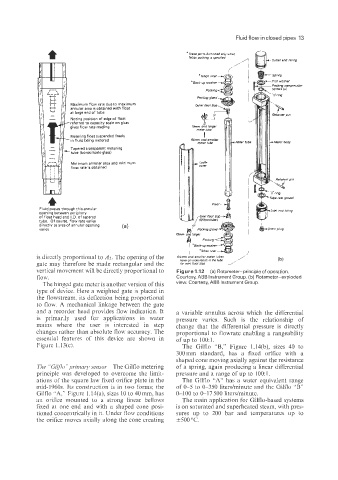

Maximum flow rate due to maximum

annular area is obtained with float

at large end of tube

Noting position of edge of float

'referred to capacity scale on glass

gives flow rate reading

Metering float suspended freely

in fluid being metered

Tapered transparent metering

-tube (borosilicate glass)

Minimum annular area and minimum

flow rate is obtained

Fluid passes through this annular

opening between periphery

of float head and I.D. of tapered

tube. Of course, flow rate varies

directly as area of annular opening (4

varies

is directly proportional to A2. The opening of the

gate may therefore be made rectangular and the

vertical movement will be directly proportional to Figure 1.12 (a) Rotameter-principle of operation.

flow. Courtesy, ABB Instrument Group. (b) Rotameter-exploded

The hinged gate meter is another version of this view. Courtesy, ABB Instrument Group.

type of device. Here a weighted gate is placed in

the flowstream, its deflection being proportional

to flow. A mechanical linkage between the gate

and a recorder head provides flow indication. It a variable annulus across which the differential

is primarily used for applications in water pressure varies. Such is the relationship of

mains where the user is interested in step change that the differential pressure is directly

changes rather than absolute flow accuracy. The proportional to flowrate enabling a rangeability

essential features of this device are shown in of up to 100: 1.

Figure l.l3(c). The Gilflo "B," Figure l.l4(b), sizes 40 to

300mm standard, has a fixed orifice with a

shaped cone moving axially against the resistance

The "Gilf7o"priinarj~ seizsoi, The Gilflo metering of a spring, again producing a linear differential

principle was developed to overcome the limit- pressure and a range of up to 100: 1.

ations of the square law fixed orifice plate in the The Gilflo "A" has a water equivalent range

mid-1960s. Its construction is in two forms: the of 0-5 to 0-350 literdminute and the Gilflo "B"

Gilflo .'A:' Figure l.l4(a), sizes 10 to 40 mm, has 0-100 to 0-17 500 liters/minute.

an orifice mounted to a strong linear bellows The main application for Gilflo-based systems

fixed at one end and with a shaped cone posi- is on saturated and superheated steam, with pres-

tioned concentrically in it. Under flow conditions sures up to 200 bar and temperatures up to

the orifice moves axially along the cone creating 1500 "C.