Page 32 - Instrumentation Reference Book 3E

P. 32

Fluid flow in closed pipes 17

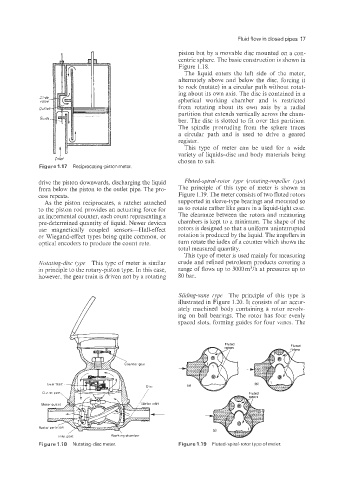

piston but by a movable disc mounted on a con-

centric sphere. The basic construction is shown in

Figure 1.18.

The liquid enters the left side of ;lie meter,

alternately above and below the disc. forcing it

to rock (nutate) in a circular path without rotat-

ing about its own axis. The disc is contained in a

spherical working chamber and is restricted

from rotating about its own axis by a radial

partition that extends vertically across the cham-

ber. The disc is slotted to fit over this partition.

The spindle protruding from the sphere traces

a circular path and is used to drive a geared

register.

This type of meter can be used for a wide

variety of liquids-disc and body materials being

Inlet chosen to suit.

Figure 1.17 Reciprocating-piston meter

drive the piston downwards, discharging the liquid Fluted-sp irai-ro tor type (r-otat ing- iinpclkei type)

from below the piston to the outlet pipe. The pro- The principle of this type of meter is shown in

cess repeats. Figure 1.19. The meter consists of two fluted rotors

As the piston reciprocates, a ratchet attached supported in sleeve-type bearings and mounted so

to the piston rod provides an actuating force for as to rotate rather like gears in a liquid-tight case.

an incremental counter, each count representing a The clearance between the rotors and measuring

pre-determined quantity of liquid. Newer devices chambers is kept tu a minimum. The shape of the

use magnetically coupled sensors-Hall-effect rotors is designed so that a uniform uninterrupted

or Wiegand-effect types being quite corninon; or rotation is produced by the liquid. The impellers in

optical enscoders to produce the count rate. turn rotate the index of a counter which shows the

total measured quantity.

This type of meter is used mainly for measuring

Nutating-disc type This type of meter is similar crude and refined petroleum products covering a

in principle to the rotary-piston type. In this case, range of flows up to 3000 m3/h at pressures up to

however, the gear train is driven not by a rotating 80 bar.

Sliding-vane type The principle of this type is

illustrated in Figure 1.20. It consists of an accur-

ately machined body containing a rotor revolv-

ing on ball bearings. The rotor has four evenly

spaced slots, forming guides for four vanes. The

Fluted

Fluted

Fluted

/

lnlel port Working chamber

Figure 1.18 Nutating-disc meter. Figure 1.1 9 Fluted-spiral-rotor type of meier.