Page 34 - Instrumentation Reference Book 3E

P. 34

Fluid flow in closed pipes 19

through nozzles to impinge on the rotors of a

small turbine located in the bypass, the rotation

of the turbine being propo-tional to flow rate.

This type of device can give moderate accuracy

over a 5:l turn-down ratio and is suitable for

liquids, gases, and steam. Bypass meters have

been used with other shunt-meter devices, including

Coanda-effect oscillatory flow meters, rotameters,

ultrasonic meters, and positive displacement meters

and multijets.

1.3.2.5 Helix meter

In this type of meter the measuring element takes

the form of a helical vane mounted centrally in

the measuring chamber with its axis along the

direction of flow as shown in Figure 1.24. The

vane consists of a hollow cylinder with accurately

formed wings. Owing to the effect of the buoy-

ancy of the liquid on the cylinder, friction

Figure 1.22 Rotating-vane type meter.

Figure 1.23 Angled-propeller meter.

of this type of meter is shown in Figure 1.23. The

propeller has three blades and is designed to give

maximum clearance in the measuring chamber,

thereby allowing maximum tolerance of sus-

pended particles. The propeller body is angled at

45" to the main flowstream and liquid passing

through the meter rotates it at a speed propor-

tional to flow rate. As the propeller goes through

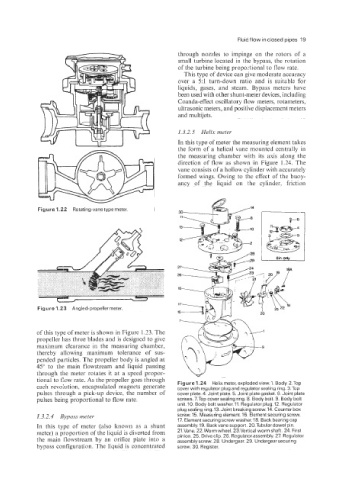

Figure 1.24 Helix meter, exploded view. 1. Body. 2.Top

each revoiution, encapsulated magnets generate cover with regulator plug and regulator sealing ring. 3.Top

pulses through a pick-up device, the number of cover plate. 4. Joint plate. 5. Joint plate gasket. 6. Joint plate

pulses being proportional to flow rate. screws. 7.Top cover sealing ring. 8. Body bolt. 9. Body bolt

unit.10. Body bolt washer.11. Regulator plug. 12. Regulator

plug sealing ring. 13. Joint breaking screw. 14. Counter box

1.3.2.4 Bypass meter screw. 15. Measuring element. 16. Element securing screw.

17. Element securing screw washer. 18. Back bearing cap

In this type of meter (also known as a shunt assembly. 19. Back vane support. 20.Tubular dowel pin.

meter) a proportion of the liquid is diverted from 21.Vane. 22.Worm wheel. 23.Vertical worm shaft. 24. First

pinion. 25. Drive clip. 26. Regulator assembly. 27. Regulator

the main flowstream by an orifice plate into a assembly screw. 28. Undergear. 29. Undergear securing

bypass configuration. The liquid is concentrated screw. 30. Register.