Page 35 - Instrumentation Reference Book 3E

P. 35

20 Measurement of flow

between its spindle and the sleeve bearings is

small. The water is directed evenly onto the vanes

by means of guides.

Transmission of the rotation from the under-

gear to the meter register is by means of ceramic

magnetic coupling.

The body of the meter is cast iron, and the

mechanism and body cover is of thermoplastic

injection moulding. The meter causes only small

head loss in operation and is suited for use in

water-distribution mains. It is available in sizes

from 40 mm up to 300 mm, respective maximum

flow rates being 24m3/h and 1540m3/h, with

accuracy of 412 percent over 20:l turn-down

ratio.

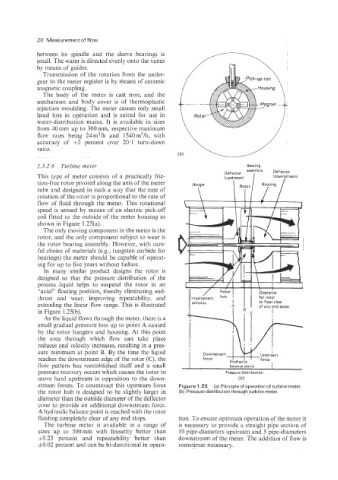

1.3.2.6 Turbine meter Bearing

Deflector

This type of meter consists of a practically fric- ~~~~~~~1 ass~blv (downstream)

tion-free rotor pivoted along the axis of the meter Hanger

tube and designed in such a way that the rate of \

rotation of the rotor is proportional to the rate of

flow of fluid through the meter. This rotational

speed is sensed by means of an electric pick-off

coil fitted to the outside of the meter housing as

shown in Figure 1.25(a).

The only moving component in the meter is the

rotor, and the only component subject to wear is

the rotor bearing assembly. However, with care- 1

ful choice of materials (e.g., tungsten carbide for

bearings) the meter should be capable of operat-

ing for up to five years without failure. I I

In many similar product designs the rotor is

designed so that the pressure distribution of the

process liquid helps to suspend the rotor in an 1

1

“axial” floating position, thereby eliminating end- hub I Clearance

,

Rotor

thrust and wear, improving repeatability, and IrnpingLnt for rotor

extending the linear flow range. This is illustrated annulus A , I to float clear

of any end stops

in Figure 1.25(b). I

As the liquid flows through the meter, there is a

small gradual pressure loss up to point A caused

by the rotor hangers and housing. At this point

the area through which flow can take place

reduces and velocity increases, resulting in a pres-

sure minimum at point B. By the time the liquid

reaches the downstream edge of the rotor (C), the

flow pattern has reestablished itself and a small I balance point

pressure recovery occurs which causes the rotor to Pressure distribution

move hard upstream in opposition to the down- (b)

stream forces. To counteract this upstream force Figure 1.25 (a) Principle of operation of turbine meter.

the rotor hub is designed to be slightly larger in (b) Pressure distribution through turbine meter.

diameter than the outside diameter of the deflector

cone to provide an additional downstream force.

A hydraulic balance point is reached with the rotor

floating completely clear of any end stops. tion. To ensure optimum operation of the meter it

The turbine meter is available in a range of is necessary to provide a straight pipe section of

sizes up to 500mm with linearity better than 10 pipe-diameters upstream and 5 pipe-diameters

10.25 percent and repeatability better than downstream of the meter. The addition of flow is

f0.02 percent and can be bi-directional in opera- sometimes necessary.