Page 31 - Instrumentation Reference Book 3E

P. 31

16 Measurement of flow

element is indicated by several possible means

including a pointer moving over a dial driven

from the measuring element by suitable gearing ”- 20 -

and a magnetically coupled sensor connected to

an electronic indicator or “flow computer.”

The extent of error, defined as the difference

between the indicated quantity and the true quan-

tity and expressed as a percentage of the true

quantity, is dependent on many factors, among

them being:

(a) The amount of clearance between the rotor

and the measuring chamber through which

liquid can pass unmetered.

(b) The amount of torque required to drive the

register. The greater the torque, the greater the

pressure drop across the measuring element,

which in turn determines the leakage rate past

the rotor. This is one reason why electronic

readout devices have become much more com-

mon in recent years, as it eliminates this error

factor.

(c) The viscosity of the liquid to be measured.

Increase in viscosity will also result in

increased pressure drop across the measuring

element, but this is compensated for by the

reduction in flow through the rotor clearances

for a given pressure drop.

The accuracy of measurement attained with a 18 Rotating PlltU”

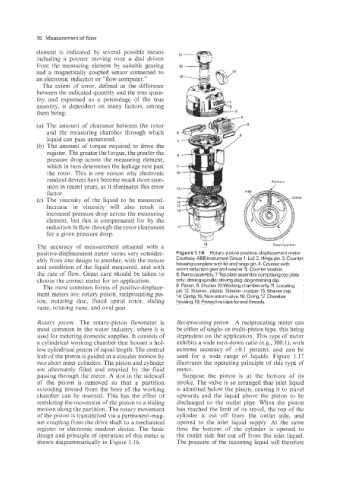

positive-displacement meter varies very consider- Figure 1.1 6 Rotary-piston positive-displacement meter.

ably from one design to another, with the nature Courtesy,ABB Instrument Group.1. Lid. 2. Hinge pin. 3. Counter

housing complete with lid and hinge pin. 4. Counter with

and condition of the liquid measured, and with worm reduction gear and washer. 5. Counter washer.

the rate of flow. Great care should be taken to 6. Ramp assembly. 7.Top plate assembly comprising top plate

choose the correct meter for an application. only; driving spindle; driving dog; dog retaining clip.

The most common forms of positive-displace- 8. Piston. 9. Shutter. 10.Working chamber only.11. Locating

ment meters are: rotary piston, reciprocating pis- pin. 12. Strainer-plastic. Strainer-copper. 13. Strainer cap.

14. Circlip.15. Non-return valve. 16.0 ring.17. Chamber

ton, nutating disc, fluted spiral rotor, sliding housing. 18. Protective caps for end threads.

vane, rotating vane, and oval gear.

Rotary piston The rotary-piston flowmeter is Reciprocating piston A reciprocating meter can

most common in the water industry, where it is be either of single- or multi-piston type, this being

used for metering domestic supplies. It consists of dependent on the application. This type of meter

a cylindrical working chamber that houses a hol- exhibits a wide turn-down ratio (e.g., 300:1), with

low cylindrical piston of equal length. The central extreme accuracy of *O.l percent, and can be

hub of the piston is guided in a circular motion by used for a wide range of liquids. Figure 1.17

two short inner cylinders. The piston and cylinder illustrates the operating principle of this type of

are alternately filled and emptied by the fluid meter.

passing through the meter. A slot in the sidewall Suppose the piston is at the bottom of its

of the piston is removed so that a partition stroke. The valve is so arranged that inlet liquid

extending inward from the bore of the working is admitted below the piston, causing it to travel

chamber can be inserted. This has the effect of upwards and the liquid above the piston to be

restricting the movement of the piston to a sliding discharged to the outlet pipe. When the piston

motion along the partition. The rotary movement has reached the limit of its travel, the top of the

of the piston is transmitted via a permanent-mag- cylinder is cut off from the outlet side, and

net coupling from the drive shaft to a mechanical opened to the inlet liquid supply. At the same

register or electronic readout device. The basic time the bottom of the cylinder is opened to

design and principle of operation of this meter is the outlet side but cut off from the inlet liquid.

shown diagrammatically in Figure 1.16. The pressure of the incoming liquid will therefore