Page 293 -

P. 293

Master Data 275

The two other broad categories of consumption-based planning are

forecast-based planning and time-phased planning. Forecast-based planning uses

historical data to estimate or forecast future consumption. Organizations use the

forecast to determine when to order materials. The advantage of this technique

over reorder point planning is that it can consider consumption patterns that

are more complex than a trend line. Time-phased planning is similar to forecast-

based planning. It is used in cases where vendors deliver only on specifi c days

of the week.

Regardless of the specifi c technique, consumption-based planning is

relatively uncomplicated compared with materials requirements planning. It

assumes that future consumption will follow the same patterns as past con-

sumption. In addition, it does not take into account dependencies between

different materials. For example, the need for wheels depends on the need to

produce bicycles. In this case, consumption-based planning is not appropri-

ate. This is because the need for wheels is not based on its past consumption;

rather, it is based on the need to make bicycles. Companies generally reserve

consumption-based planning for materials of low value or signifi cance, such as

nuts and bolts.

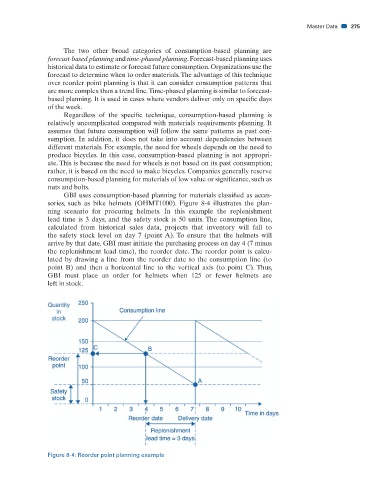

GBI uses consumption-based planning for materials classifi ed as acces-

sories, such as bike helmets (OHMT1000). Figure 8-4 illustrates the plan-

ning scenario for procuring helmets. In this example the replenishment

lead time is 3 days, and the safety stock is 50 units. The consumption line,

calculated from historical sales data, projects that inventory will fall to

the safety stock level on day 7 (point A). To ensure that the helmets will

arrive by that date, GBI must initiate the purchasing process on day 4 (7 minus

the replenishment lead time), the reorder date. The reorder point is calcu-

lated by drawing a line from the reorder date to the consumption line (to

point B) and then a horizontal line to the vertical axis (to point C). Thus,

GBI must place an order for helmets when 125 or fewer helmets are

left in stock.

Figure 8-4: Reorder point planning example

31/01/11 6:42 AM

CH008.indd 275 31/01/11 6:42 AM

CH008.indd 275