Page 162 - Intro Predictive Maintenance

P. 162

Vibration Monitoring and Analysis 153

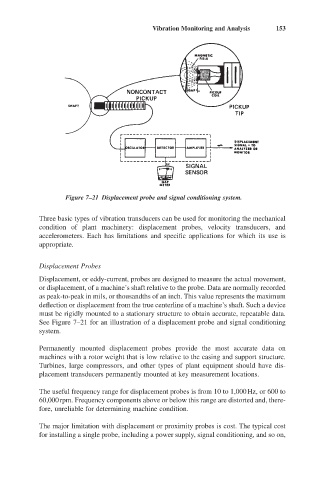

Figure 7–21 Displacement probe and signal conditioning system.

Three basic types of vibration transducers can be used for monitoring the mechanical

condition of plant machinery: displacement probes, velocity transducers, and

accelerometers. Each has limitations and specific applications for which its use is

appropriate.

Displacement Probes

Displacement, or eddy-current, probes are designed to measure the actual movement,

or displacement, of a machine’s shaft relative to the probe. Data are normally recorded

as peak-to-peak in mils, or thousandths of an inch. This value represents the maximum

deflection or displacement from the true centerline of a machine’s shaft. Such a device

must be rigidly mounted to a stationary structure to obtain accurate, repeatable data.

See Figure 7–21 for an illustration of a displacement probe and signal conditioning

system.

Permanently mounted displacement probes provide the most accurate data on

machines with a rotor weight that is low relative to the casing and support structure.

Turbines, large compressors, and other types of plant equipment should have dis-

placement transducers permanently mounted at key measurement locations.

The useful frequency range for displacement probes is from 10 to 1,000Hz, or 600 to

60,000rpm. Frequency components above or below this range are distorted and, there-

fore, unreliable for determining machine condition.

The major limitation with displacement or proximity probes is cost. The typical cost

for installing a single probe, including a power supply, signal conditioning, and so on,