Page 164 - Intro Predictive Maintenance

P. 164

Vibration Monitoring and Analysis 155

4

SENSITIVE AXIS

3

2

1

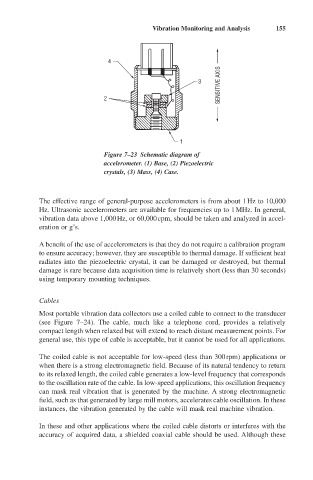

Figure 7–23 Schematic diagram of

accelerometer. (1) Base, (2) Piezoelectric

crystals, (3) Mass, (4) Case.

The effective range of general-purpose accelerometers is from about 1Hz to 10,000

Hz. Ultrasonic accelerometers are available for frequencies up to 1MHz. In general,

vibration data above 1,000Hz, or 60,000cpm, should be taken and analyzed in accel-

eration or g’s.

A benefit of the use of accelerometers is that they do not require a calibration program

to ensure accuracy; however, they are susceptible to thermal damage. If sufficient heat

radiates into the piezoelectric crystal, it can be damaged or destroyed, but thermal

damage is rare because data acquisition time is relatively short (less than 30 seconds)

using temporary mounting techniques.

Cables

Most portable vibration data collectors use a coiled cable to connect to the transducer

(see Figure 7–24). The cable, much like a telephone cord, provides a relatively

compact length when relaxed but will extend to reach distant measurement points. For

general use, this type of cable is acceptable, but it cannot be used for all applications.

The coiled cable is not acceptable for low-speed (less than 300rpm) applications or

when there is a strong electromagnetic field. Because of its natural tendency to return

to its relaxed length, the coiled cable generates a low-level frequency that corresponds

to the oscillation rate of the cable. In low-speed applications, this oscillation frequency

can mask real vibration that is generated by the machine. A strong electromagnetic

field, such as that generated by large mill motors, accelerates cable oscillation. In these

instances, the vibration generated by the cable will mask real machine vibration.

In these and other applications where the coiled cable distorts or interferes with the

accuracy of acquired data, a shielded coaxial cable should be used. Although these