Page 163 - Intro Predictive Maintenance

P. 163

154 An Introduction to Predictive Maintenance

1

6

2

3

4

5

SENSITIVE AXIS

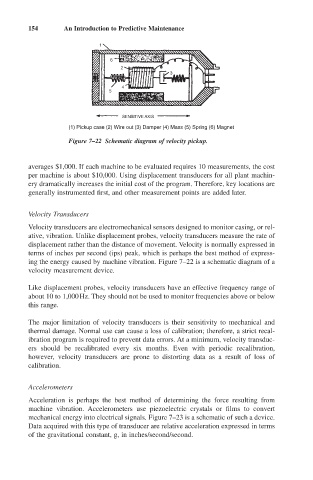

(1) Pickup case (2) Wire out (3) Damper (4) Mass (5) Spring (6) Magnet

Figure 7–22 Schematic diagram of velocity pickup.

averages $1,000. If each machine to be evaluated requires 10 measurements, the cost

per machine is about $10,000. Using displacement transducers for all plant machin-

ery dramatically increases the initial cost of the program. Therefore, key locations are

generally instrumented first, and other measurement points are added later.

Velocity Transducers

Velocity transducers are electromechanical sensors designed to monitor casing, or rel-

ative, vibration. Unlike displacement probes, velocity transducers measure the rate of

displacement rather than the distance of movement. Velocity is normally expressed in

terms of inches per second (ips) peak, which is perhaps the best method of express-

ing the energy caused by machine vibration. Figure 7–22 is a schematic diagram of a

velocity measurement device.

Like displacement probes, velocity transducers have an effective frequency range of

about 10 to 1,000Hz. They should not be used to monitor frequencies above or below

this range.

The major limitation of velocity transducers is their sensitivity to mechanical and

thermal damage. Normal use can cause a loss of calibration; therefore, a strict recal-

ibration program is required to prevent data errors. At a minimum, velocity transduc-

ers should be recalibrated every six months. Even with periodic recalibration,

however, velocity transducers are prone to distorting data as a result of loss of

calibration.

Accelerometers

Acceleration is perhaps the best method of determining the force resulting from

machine vibration. Accelerometers use piezoelectric crystals or films to convert

mechanical energy into electrical signals. Figure 7–23 is a schematic of such a device.

Data acquired with this type of transducer are relative acceleration expressed in terms

of the gravitational constant, g, in inches/second/second.