Page 309 - System on Package_ Miniaturization of the Entire System

P. 309

Radio Fr equency System-on-Package (RF SOP) 283

performance requirements. In addition, for many applications, the capacitance value

has to be stable within 0.3 percent over a 100°C range of temperature (TCC of <30 ppm/°C).

While the high Q and low TCC of capacitors in LTCC RF modules have been demonstrated

for decades [82–83], the dielectric mainly consists of ceramics and glass and requires

high-temperature crystallization, which is not congruous with low-temperature organic

substrate processing. LTCC technology is also limited by its high cost, incompatibility

with large-area processing, and low component density integration capability. Nevertheless,

LTCC technology for RF modules is still prevalent because of the low loss, good thermal

conductivity, and stability for high-frequency applications. The disadvantages of LTCC

technology can be overcome with LCP-based RF components [84]. Hence, there is an

increasing trend toward LCP-based RF circuits. However, the low dielectric constant of

this material makes the RF components and modules larger in size, which may limit the

component integration density; increases coupling between the components; and

degrades the total system performance. Furthermore, low-loss and low-TCC polymers

such as LCP and PTFE are not easily amenable to thin films, without compromising the

electrical properties.

Low-loss and high-Q capacitors have been achieved on a silicon platform using a

thin-film BCB buildup structure for RF wafer-level SOP functions [85]. High-K and low-

loss pyrochlore thin-film in organic substrate has also been explored [86]. This technology

enables complete RF integration for various applications such as matching networks,

filters, and even tunable components such as phase shifters. On the other hand, new

and novel compositions to achieve high Q and low TCC have been pursued using the

composite approach with ceramic fillers and low-loss, high-Q polymers. For example,

an LCP-based polymer composite has been engineered to replace LTCC components

such as capacitors.

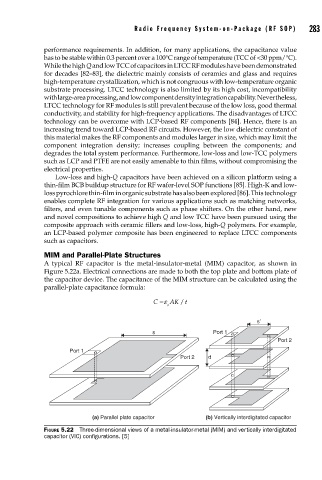

MIM and Parallel-Plate Structures

A typical RF capacitor is the metal-insulator-metal (MIM) capacitor, as shown in

Figure 5.22a. Electrical connections are made to both the top plate and bottom plate of

the capacitor device. The capacitance of the MIM structure can be calculated using the

parallel-plate capacitance formula:

C =ε AK t

/

o

s′

s Port 1

Port 2

Port 1

Port 2 d

(a) Parallel plate capacitor (b) Vertically interdigitated capacitor

FIGURE 5.22 Three-dimensional views of a metal-insulator-metal (MIM) and vertically interdigitated

capacitor (VIC) confi gurations. [5]