Page 305 - System on Package_ Miniaturization of the Entire System

P. 305

Radio Fr equency System-on-Package (RF SOP) 279

Via

Au (2 μm)

Polyimide

Ground

plane

Au (1 μm)

Si Substrate (625 μm, ρ = 30 cm)

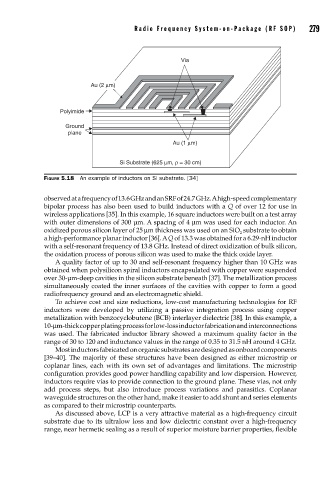

FIGURE 5.18 An example of inductors on Si substrate. [34]

observed at a frequency of 13.6 GHz and an SRF of 24.7 GHz. A high-speed complementary

bipolar process has also been used to build inductors with a Q of over 12 for use in

wireless applications [35]. In this example, 16 square inductors were built on a test array

with outer dimensions of 300 μm. A spacing of 4 μm was used for each inductor. An

oxidized porous silicon layer of 25 μm thickness was used on an SiO substrate to obtain

2

a high-performance planar inductor [36]. A Q of 13.3 was obtained for a 6.29-nH inductor

with a self-resonant frequency of 13.8 GHz. Instead of direct oxidization of bulk silicon,

the oxidation process of porous silicon was used to make the thick oxide layer.

A quality factor of up to 30 and self-resonant frequency higher than 10 GHz was

obtained when polysilicon spiral inductors encapsulated with copper were suspended

over 30-μm-deep cavities in the silicon substrate beneath [37]. The metallization process

simultaneously coated the inner surfaces of the cavities with copper to form a good

radiofrequency ground and an electromagnetic shield.

To achieve cost and size reductions, low-cost manufacturing technologies for RF

inductors were developed by utilizing a passive integration process using copper

metallization with benzocyclobutene (BCB) interlayer dielectric [38]. In this example, a

10-μm-thick copper plating process for low-loss inductor fabrication and interconnections

was used. The fabricated inductor library showed a maximum quality factor in the

range of 30 to 120 and inductance values in the range of 0.35 to 31.5 nH around 4 GHz.

Most inductors fabricated on organic substrates are designed as onboard components

[39–40]. The majority of these structures have been designed as either microstrip or

coplanar lines, each with its own set of advantages and limitations. The microstrip

configuration provides good power handling capability and low dispersion. However,

inductors require vias to provide connection to the ground plane. These vias, not only

add process steps, but also introduce process variations and parasitics. Coplanar

waveguide structures on the other hand, make it easier to add shunt and series elements

as compared to their microstrip counterparts.

As discussed above, LCP is a very attractive material as a high-frequency circuit

substrate due to its ultralow loss and low dielectric constant over a high-frequency

range, near hermetic sealing as a result of superior moisture barrier properties, flexible