Page 310 - System on Package_ Miniaturization of the Entire System

P. 310

284 Cha pte r F i v e

–12

where C is the capacitance (F), e is the permittivity of free space (8.854 × 10 F/m), A is

o

the area (m ), and t is the thickness (m). Insertion of a dielectric between the parallel

2

plates increases the capacitance by an amount proportional to the dielectric constant, K.

The dielectric constant is defined by K =εε/ , where e is the permittivity of the

o

dielectric. For large capacitors such as the RF ground capacitors, however, the electrode

size becomes too large for the MIM configuration to handle. The interdigital topology

tends to require a bigger area since the electric flux is generated laterally instead of

vertically such as in the MIM, which allows more electrode coverage.

An alternative capacitor implementation to the MIM topology [5] was proposed using

the vertically interdigitated configuration (VIC) shown in Figure 5.22b. The MIM structure

consisting of a dielectric layer sandwiched between two square plates of widths in

Figure 5.22a implements this type of capacitor, neglecting the higher-order excitation

mode. This capacitor can also be implemented by a parallel combination of pairs of plates

of smaller size. The plate size can be made smaller as more plates are deployed on many

dielectric layers. VIC topology occupies nearly an order of magnitude less area than the

MIM while maintaining comparable performance.

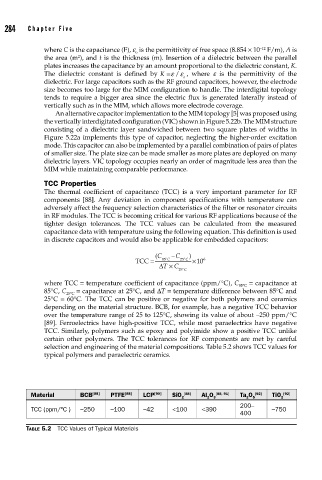

TCC Properties

The thermal coefficient of capacitance (TCC) is a very important parameter for RF

components [88]. Any deviation in component specifications with temperature can

adversely affect the frequency selection characteristics of the filter or resonator circuits

in RF modules. The TCC is becoming critical for various RF applications because of the

tighter design tolerances. The TCC values can be calculated from the measured

capacitance data with temperature using the following equation. This definition is used

in discrete capacitors and would also be applicable for embedded capacitors:

(C −C )

TCC = 85 C 25 C ×10 6

Δ T × C

25 C

where TCC = temperature coefficient of capacitance (ppm/°C), C 85°C = capacitance at

85°C, C 25°C = capacitance at 25°C, and ΔT = temperature difference between 85°C and

25°C = 60°C. The TCC can be positive or negative for both polymers and ceramics

depending on the material structure. BCB, for example, has a negative TCC behavior

over the temperature range of 25 to 125°C, showing its value of about –250 ppm/°C

[89]. Ferroelectrics have high-positive TCC, while most paraelectrics have negative

TCC. Similarly, polymers such as epoxy and polyimide show a positive TCC unlike

certain other polymers. The TCC tolerances for RF components are met by careful

selection and engineering of the material compositions. Table 5.2 shows TCC values for

typical polymers and paraelectric ceramics.

Material BCB [88] PTFE [88] LCP [90] SiO 2 [88] Al O 3 [88, 91] Ta O 5 [92] TiO 2 [92]

2

2

200–

TCC (ppm/°C ) –250 –100 –42 <100 <390 –750

400

TABLE 5.2 TCC Values of Typical Materials