Page 114 - Sami Franssila Introduction to Microfabrication

P. 114

8

Pattern Generation

A pattern generation tool transcribes the circuit design

data into a physical structure. It must be able to expose

single pixels and expose them fairly fast, since designs

can consist of millions of pixels. The first pattern

generators were optomechanical shutter systems with a Wafer

flash bulb. Aperture blades were sized and positioned,

followed by the exposing flash. After mechanical ~300 mm

movement of the wafer, the aperture sizing operation

and flashing was repeated, with operating frequency of

ca. 1 Hz. This method was employed in the early era of Stage

microfabrication when linewidths were above 10 µm. Chip scan

The most precise way of delineating structures is ~25 mm

by drawing a single feature with a focused beam

of electrons, ions or photons. This is faster than the

mechanical aperture method but still very slow. It has Main-field

three main applications: Beam

stepping

5 mm

1. Direct writing for ultimate resolution.

2. Direct writing in research and small series produc-

tion. Sub-field

3. Writing photomasks for optical lithography.

250 µm

Beam writing is several orders of magnitude slower

than optical lithography with photomasks but it offers

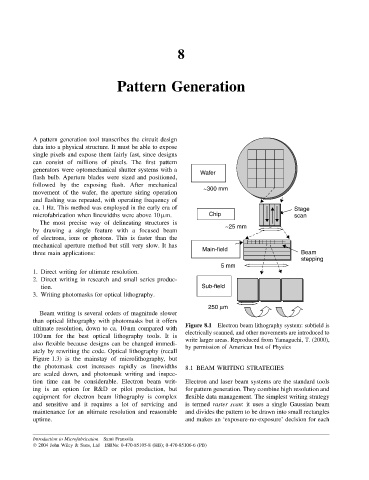

Figure 8.1 Electron beam lithography system: subfield is

ultimate resolution, down to ca. 10 nm compared with

electrically scanned, and other movements are introduced to

100 nm for the best optical lithography tools. It is

write larger areas. Reproduced from Yamaguchi, T. (2000),

also flexible because designs can be changed immedi-

by permission of American Inst of Physics

ately by rewriting the code. Optical lithography (recall

Figure 1.3) is the mainstay of microlithography, but

the photomask cost increases rapidly as linewidths 8.1 BEAM WRITING STRATEGIES

are scaled down, and photomask writing and inspec-

tion time can be considerable. Electron beam writ- Electron and laser beam systems are the standard tools

ing is an option for R&D or pilot production, but for pattern generation. They combine high resolution and

equipment for electron beam lithography is complex flexible data management. The simplest writing strategy

and sensitive and it requires a lot of servicing and is termed raster scan: it uses a single Gaussian beam

maintenance for an ultimate resolution and reasonable and divides the pattern to be drawn into small rectangles

uptime. and makes an ‘exposure-no-exposure’ decision for each

Introduction to Microfabrication Sami Franssila

2004 John Wiley & Sons, Ltd ISBNs: 0-470-85105-8 (HB); 0-470-85106-6 (PB)