Page 143 - Sami Franssila Introduction to Microfabrication

P. 143

122 Introduction to Microfabrication

Figure 11.2 Undercutting in isotropic etching: wide lines are narrowed but narrow lines are completely undercut

and released

Oxidized SiO 2

1 2

Si slab Thinned Si slab (300 nm)

SiO 2

Si substrate

PMMA Patterned PMMA Holes etched into Si slab

3 4 5

Patterned, free-standing

Patterned Si slab Si membrane (300 nm)

6 7

Thinned Si substrate

Undercut air region SiO 2

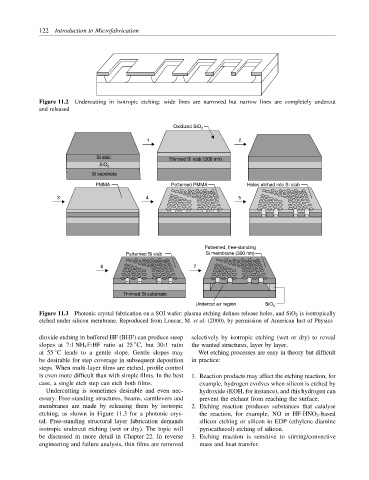

Figure 11.3 Photonic crystal fabrication on a SOI wafer: plasma etching defines release holes, and SiO 2 is isotropically

etched under silicon membrane. Reproduced from Loncar, M. et al. (2000), by permission of American Inst of Physics

dioxide etching in buffered HF (BHF) can produce steep selectively by isotropic etching (wet or dry) to reveal

◦

slopes at 7:1 NH 4 F:HF ratio at 25 C, but 30:1 ratio the wanted structures, layer by layer.

◦

at 55 C leads to a gentle slope. Gentle slopes may Wet etching processes are easy in theory but difficult

be desirable for step coverage in subsequent deposition in practice:

steps. When multi-layer films are etched, profile control

is even more difficult than with simple films. In the best 1. Reaction products may affect the etching reaction, for

case, a single etch step can etch both films. example, hydrogen evolves when silicon is etched by

Undercutting is sometimes desirable and even nec- hydroxide (KOH, for instance), and this hydrogen can

essary. Free-standing structures, beams, cantilevers and prevent the etchant from reaching the surface.

membranes are made by releasing them by isotropic 2. Etching reaction produces substances that catalyse

etching, as shown in Figure 11.3 for a photonic crys- the reaction, for example, NO in HF-HNO 3 -based

tal. Free-standing structural layer fabrication demands silicon etching or silicon in EDP (ethylene diamine

isotropic undercut etching (wet or dry). The topic will pyrocathecol) etching of silicon.

be discussed in more detail in Chapter 22. In reverse 3. Etching reaction is sensitive to stirring/convective

engineering and failure analysis, thin films are removed mass and heat transfer.