Page 145 - Sami Franssila Introduction to Microfabrication

P. 145

124 Introduction to Microfabrication

2.0 Electropolishing

Log i (mA/cm 2 ) 1.0 Transition region HF

0

Porous silicon

Si Si Pt Pt

−1.0

−1.0 −0.5 0 0.5 1.0 1.5

Log [HF] (vol %)

(a) (b)

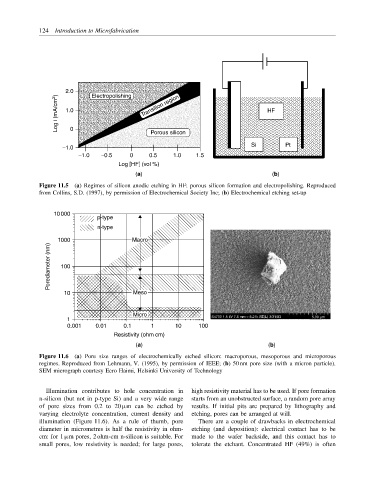

Figure 11.5 (a) Regimes of silicon anodic etching in HF: porous silicon formation and electropolishing. Reproduced

from Collins, S.D. (1997), by permission of Electrochemical Society Inc; (b) Electrochemical etching set-up

10000

p-type

n-type

1000 Macro

Porediameter (nm) 100

10 Meso

Micro S4700 1.5 kV 7.6 mm × 8.21k SE(L) 3/31/03

1 5.00 µm

0.001 0.01 0.1 1 10 100

Resistivity (ohm cm)

(a) (b)

Figure 11.6 (a) Pore size ranges of electrochemically etched silicon: macroporous, mesoporous and microporous

regimes. Reproduced from Lehmann, V. (1995), by permission of IEEE; (b) 50 nm pore size (with a micron particle).

SEM micrograph courtesy Eero Haimi, Helsinki University of Technology

Illumination contributes to hole concentration in high resistivity material has to be used. If pore formation

n-silicon (but not in p-type Si) and a very wide range starts from an unobstructed surface, a random pore array

of pore sizes from 0.2 to 20 µm can be etched by results. If initial pits are prepared by lithography and

varying electrolyte concentration, current density and etching, pores can be arranged at will.

illumination (Figure 11.6). As a rule of thumb, pore There are a couple of drawbacks in electrochemical

diameter in micrometres is half the resistivity in ohm- etching (and deposition): electrical contact has to be

cm: for 1 µm pores, 2 ohm-cm n-silicon is suitable. For made to the wafer backside, and this contact has to

small pores, low resistivity is needed; for large pores, tolerate the etchant. Concentrated HF (49%) is often