Page 160 - Sami Franssila Introduction to Microfabrication

P. 160

Wafer Cleaning and Surface Preparation 139

0.015

d AS d SS

t AS m t SS

0.5% HF 6 h

0.010 DI rinse

Absorbance 4 h

0.005 2 h

1 h

0.25 h

0.000

3000 2950 2900 2850

−1

Wavenumber (cm )

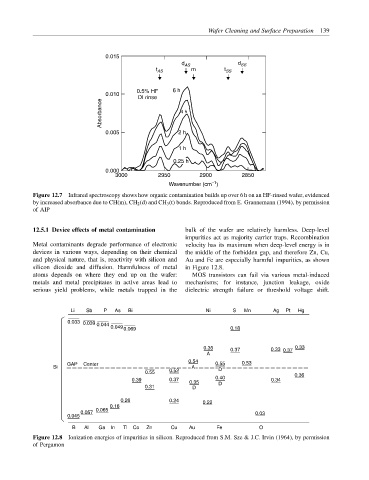

Figure 12.7 Infrared spectroscopy shows how organic contamination builds up over 6 h on an HF-rinsed wafer, evidenced

by increased absorbance due to CH(m), CH 2 (d) and CH 3 (t) bonds. Reproduced from E. Grannemann (1994), by permission

of AIP

12.5.1 Device effects of metal contamination bulk of the wafer are relatively harmless. Deep-level

impurities act as majority carrier traps. Recombination

Metal contaminants degrade performance of electronic velocity has its maximum when deep-level energy is in

devices in various ways, depending on their chemical the middle of the forbidden gap, and therefore Zn, Cu,

and physical nature, that is, reactivity with silicon and Au and Fe are especially harmful impurities, as shown

silicon dioxide and diffusion. Harmfulness of metal in Figure 12.8.

atoms depends on where they end up on the wafer: MOS transistors can fail via various metal-induced

metals and metal precipitates in active areas lead to mechanisms; for instance, junction leakage, oxide

serious yield problems, while metals trapped in the dielectric strength failure or threshold voltage shift.

Li Sb P As Bi Ni S Mn Ag Pt Hg

0.033 0.039

0.044

0.049 0.069 0.18

0.35 0.37 0.33 0.37 0.33

A

0.54

GAP Center 0.55 0.53

Si A D

0.55 0.52 0.36

0.39 0.37 0.35 0.40 0.34

0.31 D D

0.26 0.24 0.22

0.16

0.065

0.057 0.03

0.045

B Al Ga In Tl Co Zn Cu Au Fe O

Figure 12.8 Ionization energies of impurities in silicon. Reproduced from S.M. Sze & J.C. Irvin (1964), by permission

of Pergamon